Introduction

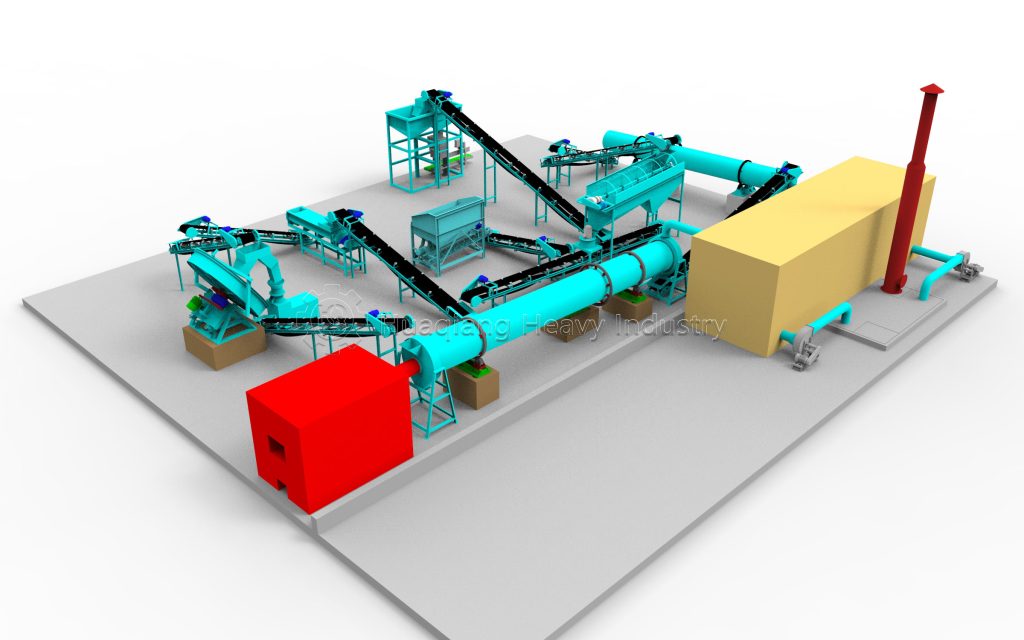

The disc granulation production line is an efficient and cost-effective solution for fertilizer production, particularly suitable for small and medium-sized enterprises (SMEs). It features a short production process, simple structure, low investment, and easy operation, enabling quick production setup and profitability. Additionally, the line offers wide adaptability to raw materials, allowing for the production of various types of fertilizers, including inorganic compound fertilizers, organic fertilizers, organic-inorganic compound fertilizers, and bio-organic fertilizers.

When selecting equipment, partnering with an experienced fertilizer machine manufacturer ensures optimal performance. For specialized NPK production line requirements, the NPK fertilizer production line integrates specific equipment like the NPK fertilizer granulator machine to handle complex nutrient formulas. The core of many systems is the disc granulator, a versatile disc granulator machine known for its high granulation efficiency and uniform particle size. This robust machine is pivotal in the fertilizer granulation process, transforming powdered raw materials into durable, spherical granules. This complete solution empowers SMEs to produce high-quality, market-ready fertilizers efficiently and sustainably, maximizing return on investment.

Advantages of Disc Granulation Line

The disc granulation line offers the following significant advantages:

- Short Production Process:The streamlined process ensures high efficiency from raw materials to finished products, reducing intermediate steps and energy consumption.

- Simple Structure:The equipment is designed for easy maintenance, low failure rates, and long service life.

- Low Investment:Compared to other granulation technologies, the initial investment and operational costs are lower, making it ideal for SMEs with limited capital.

- Easy Operation:With a high degree of automation, operators can quickly learn and manage the process, improving productivity.

Raw Material Adaptability

The disc granulator is highly adaptable to a wide range of raw materials, including:

- Nitrogen Sources:Urea, ammonium chloride, ammonium sulfate, etc.

- Phosphorus Sources:Calcium, heavy calcium, etc.

- Potassium Sources:Potassium chloride, potassium sulfate, etc.

The flexible combination of these materials enables the production of fertilizers with nitrogen, phosphorus, and potassium nutrient content ranging from 20% to 48%, meeting the nutritional needs of various crops.

Applications

The disc granulation line can be widely applied to produce the following types of fertilizers:

- Inorganic Compound Fertilizers:Produced through chemical synthesis, these fertilizers offer high nutrient content and rapid effects.

- Organic Fertilizers:Made from organic waste (e.g., livestock manure, crop straw), these fertilizers are environmentally friendly and improve soil structure.

- Organic-Inorganic Compound Fertilizers:Combining the benefits of organic and inorganic nutrients, these fertilizers provide both quick nutrient supply and long-term soil improvement.

- Bio-Organic Fertilizers:These fertilizers incorporate beneficial microorganisms into organic fertilizers to promote crop growth and suppress diseases.

Conclusion

With its efficiency, cost-effectiveness, and flexibility, the disc granulation line is an ideal choice for small and medium-sized fertilizer producers. It not only reduces investment and operational costs but also adapts to diverse raw materials and production needs, helping businesses thrive in a competitive market. As global attention to sustainable agriculture grows, the disc granulation line will play an increasingly important role in the future.