In modern precision agriculture, the ability to provide crops with tailored nutrition is paramount. The npk blending fertilizer production line (also known as BB Fertilizer Line) offers a uniquely agile solution. Unlike chemical compound fertilizers that fuse nutrients within each granule, this line creates customized nutrient packages through the precise physical blending of different granular raw materials. It is the embodiment of flexibility, precision, and efficiency in meeting specific soil and crop needs.

Core Advantages: Agile, Precise, Cost-Effective

The NPK Blending Line stands out for its straightforward yet highly effective approach to fertilizer production:

Unmatched Formulation Flexibility: This is its defining strength. The production line can be reconfigured within minutes to produce any N-P-K ratio, along with secondary and micronutrients (like Sulfur, Calcium, Zinc). It enables true “prescription farming,” allowing blends to be tailored to specific soil test results, crop types, and growth stages.

Precise Nutrient Accuracy: By using high-purity, granular base materials (e.g., granular urea, diammonium phosphate, muriate of potash), the exact amount of each nutrient is known and controlled. The advanced computerized batching system ensures the final blend matches the target formula with a high degree of accuracy.

Rapid Production & Economic Operation: The process is purely physical—no chemical reactions, heating, or drying are required. This leads to very short batch cycle times (typically 15-30 minutes), low energy consumption, and significantly lower capital investment compared to complex compound fertilizer granulation plants. It is ideal for small-to-medium scale production and regional blenders.

Fast Market Response: The ability to switch formulas quickly allows producers to respond immediately to seasonal demand changes or custom orders from large farms. It effectively bridges the gap between large-scale raw material production and localized, specialized fertilizer needs.

Preservation of Raw Material Properties: Each base fertilizer granule retains its original physical and chemical characteristics. This ensures predictable nutrient release patterns in the soil and avoids potential compatibility issues that can arise from chemical processing.

The Production Process: A Streamlined Physical Workflow

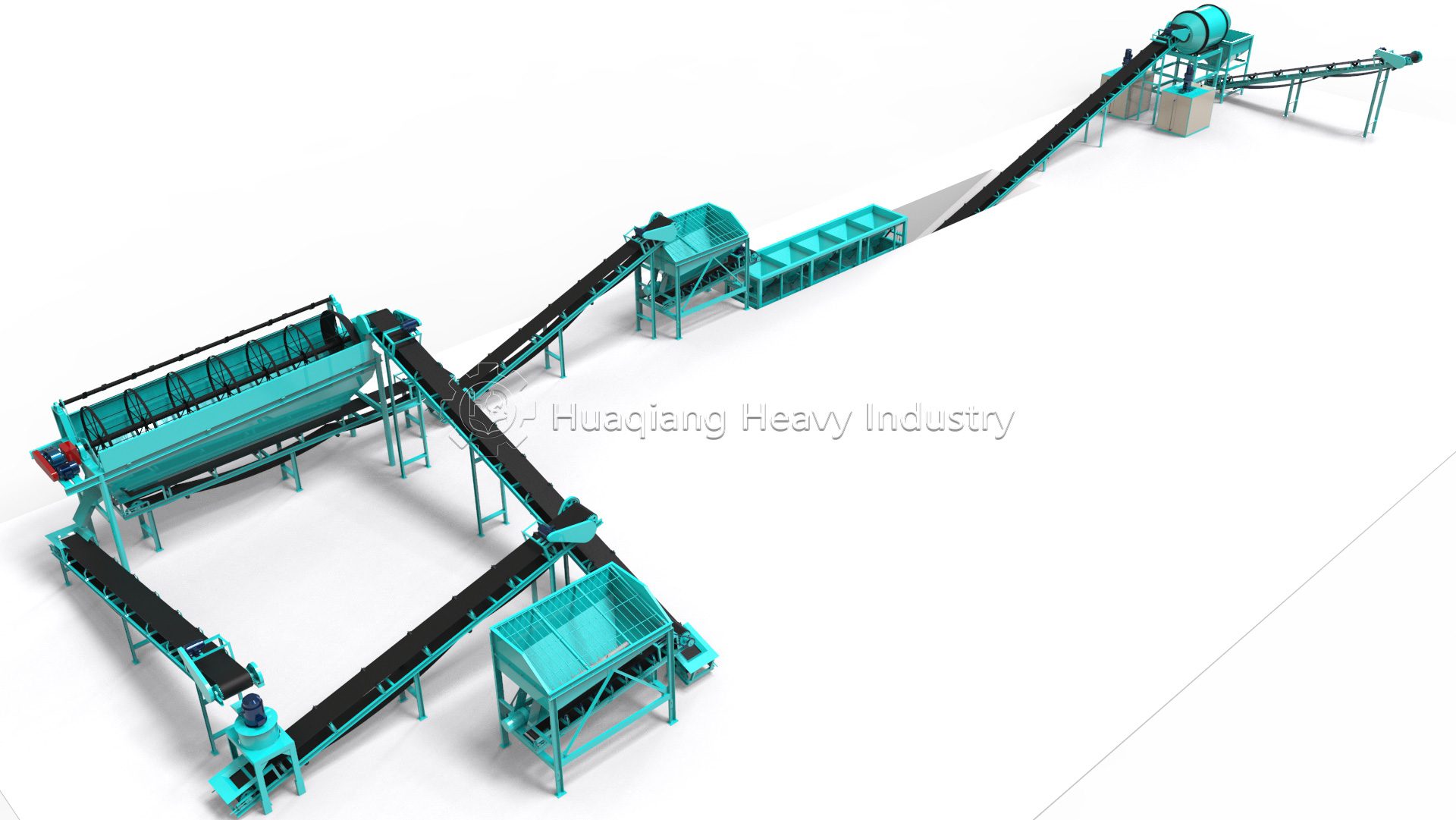

The NPK Blending Line is a model of efficiency, transforming bulk materials into custom blends through a clear, automated sequence:

Raw Material Receiving & Storage:

Key Equipment: Bulk Silos, Bag Dump Stations.

Different granular base fertilizers are stored separately in dedicated silos or bag warehouses to prevent contamination and moisture absorption.

Automated Precision Batching:

Key Equipment: Computer Control System, Multiple Precision Feeders (Loss-in-Weight or Volumetric).

The heart of the line. The control system activates individual feeders under each silo. Each feeder discharges a specific raw material at a precisely controlled rate according to the digital recipe. This step determines the ultimate accuracy of the blend.

High-Speed, Uniform Mixing:

Key Equipment: Horizontal Mixer or Batch Vertical Disc Mixer.

The batched materials are conveyed to a high-capacity mixer. Within 2-5 minutes of mixing, the different granules are thoroughly and uniformly blended to ensure every grab sample from the batch has the exact same nutrient composition.

Finished Product Handling & Packaging:

Key Equipment: Surge Hopper, Automatic Weighing and Bagging Scale, Sewing/Palletizing System.

The blended fertilizer is discharged into a surge hopper and then fed to automated packers. It is weighed, bagged, sealed, and palletized with minimal manual intervention, ready for dispatch.

Dust Control & Automation:

Key Equipment: Centralized Dust Collection System, PLC Control Panel.

Enclosed conveying and mixing points are connected to dust collectors to maintain a clean plant environment. The entire process is managed by a Programmable Logic Controller (PLC) for consistent, reliable operation.

Key Components & Technology

Intelligent Batching System: The core brain, ensuring micro-scale precision in macro-scale production.

Gentle Yet Thorough Mixer: Designed to achieve homogeneity without damaging or degrading the granular materials.

Robust Material Handling: Ensures smooth, consistent flow from storage to mixing to packaging.

Integrated Quality Control: May include automated sampling systems to verify blend uniformity.

Comparison with NPK Compound Granulation Line

NPK Blending (BB) Line: Physical mixture of granules. Nutrients exist in separate particles. Advantages: Extreme flexibility, fast formula change, low cost. Considerations: Potential for segregation if particles differ greatly in size/density.

NPK Compound Granulation Line: Chemical fusion within each granule. Nutrients are uniformly distributed in every pellet. Advantages: Superior product uniformity and physical strength, ideal for long supply chains. Considerations: Higher investment, less flexible, involves chemical processes and drying.