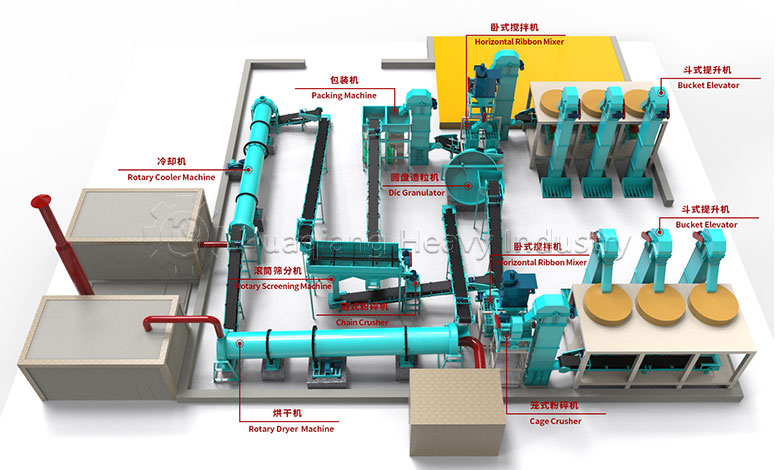

In the vast landscape of industrial production, the disc granulation production line acts like a skilled magician, transforming various powdered raw materials into uniform, well-formed granules through its unique rotating charm. This sophisticated fertilizer granulator serves as the cornerstone equipment in comprehensive production systems, seamlessly integrating with upstream components like the NPK blending machine and downstream elements including the automated fertilizer packing machine.

The versatility of this granulation technology enables its application across diverse production environments, from specialized organic fertilizer production line setups to complex NPK fertilizer production line operations. As the central fertilizer granulator within these integrated systems, the disc granulator demonstrates remarkable compatibility with various material formulations and production requirements.

This seemingly simple equipment shines with distinctive brilliance across numerous industrial sectors, thanks to its exceptional adaptability and outstanding performance. Whether operating within a complete disc granulation production line or serving as a key component in larger manufacturing processes, its ability to work in harmony with both blending and packaging equipment makes it an indispensable asset in modern fertilizer production.

Diverse Applications: An All-Rounder Across Industries

Fertilizer Production

As the core equipment in granulation technology, disc granulators play a crucial role in producing organic fertilizers, compound fertilizers, and bio-fertilizers. They transform materials like livestock manure and straw into granular fertilizers that are easy to store and transport, significantly improving fertilizer utilization efficiency. In compound fertilizer production, precise proportioning of basic fertilizers like nitrogen, phosphorus, and potassium enables the production of specialized fertilizers tailored to different crop needs.

Metallurgical Industry

In the metallurgical sector, disc granulators specialize in processing metal ore powders such as iron ore powder and manganese ore powder. Through the granulation process, these ore powders are transformed into uniform granules, facilitating subsequent sintering and smelting processes while significantly enhancing resource utilization and reducing production costs, contributing to the green development of the metallurgical industry.

Building Materials Manufacturing

In the building materials industry, disc granulators are used to produce cement raw material particles and ceramsite sand. By granulating cement raw materials, they not only improve the combustion performance of the materials but also enhance the quality of the final cement product, providing superior raw materials for the construction industry.

Chemical Raw Material Processing

In the chemical industry, disc granulators handle the granulation of chemical raw materials such as catalysts, pigments, and detergents. Chemical products processed through granulation demonstrate improved flowability, stability, and performance, meeting the stringent quality requirements of modern chemical production.

Core Advantages: Why It’s Highly Valued

Exceptional Adaptability

Capable of processing various types of raw materials, from organic waste to metal ore powders, demonstrating remarkable versatility

High Efficiency & Energy Saving

Lower energy consumption compared to other granulation equipment, offering more competitive operating costs

Quality Assurance

Produces granules with high uniformity, excellent strength, and reliable, stable quality

Easy Operation

High degree of automation, convenient maintenance, significantly reducing labor costs

Particularly noteworthy is the amazing flexibility disc granulators demonstrate when processing different materials. Whether dealing with viscous organic materials or dry mineral powders, they can achieve optimal granulation results by adjusting parameters such as disc inclination angle and rotation speed. This powerful adaptability makes them the preferred equipment in numerous industries.

Future Outlook: Continuously Innovating Industrial Tool

With continuous technological advancements, disc granulators are evolving toward greater intelligence and precision. Modern disc granulators are already equipped with advanced automatic control systems that monitor the granulation process in real-time, ensuring every granule reaches its ideal state. In the future, with the application of new materials and processes, disc granulators will undoubtedly play important roles in even more fields.

The disc granulator represents not only an outstanding example of industrial granulation technology but also a key force driving development across multiple industries. From farmlands to mines, from chemical plants to construction sites, this equipment quietly supports the operation of modern industry with its reliable performance and exceptional adaptability. Choosing a disc granulator means choosing an efficient, reliable, and environmentally friendly production method.