Introduction: The Revolution from Waste to Golden Granules

In today’s world, where the concept of sustainable development is sweeping across the globe, the agricultural sector is undergoing a quiet yet profound transformation. The emergence of new-type organic fertilizer granulators shines like a brilliant star, illuminating the future of green agriculture. However, this machine is just the beginning of the story—what’s truly fascinating is how it collaborates with a series of precision equipment to build an ecosystem for resource recycling.

Core Breakthroughs in Granulator Technology

New-type organic fertilizer granulator employ innovative dual-roller extrusion or rotary granulation technology, capable of transforming loose and easily scattered organic materials into uniform, moderately strong granular fertilizers. This transformation is not merely a change in physical form; it represents a leap in fertilizer efficiency.

Compared to traditional methods, new-type granulators offer four significant advantages:

Enhanced nutrient slow-release effect: Granular structure slows nutrient release, reducing loss

Improved application convenience: Standardized granules facilitate mechanized application

Better storage stability: Reduced moisture absorption and caking, extended shelf life

Reduced environmental impact: Minimized dust pollution, improved working conditions

Collaborative Equipment System: Efficient Organic Fertilizer Production Lines

The efficient operation of granulators relies on the seamless coordination of supporting equipment. A complete modern organic fertilizer production line includes the following key stages:

Crushing and Pre-treatment System

The first step in the production process involves thorough processing by efficient cage crusher. Whether agricultural waste, livestock manure, or urban organic waste, all can be transformed into uniformly fine base materials through powerful crushing equipment. The quality of this stage directly determines the final product’s quality.

Precise Ingredient Batching and Mixing

Mixers function like experienced chefs, accurately proportioning various raw materials to ensure the perfect balance of key elements such as nitrogen, phosphorus, potassium, and trace minerals. Advanced automated control systems can precisely adjust ingredient ratios according to preset formulas, guaranteeing consistency across production batches.

Fermentation and Maturation Process

For organic fertilizers requiring fermentation, specialized fermentation equipment such as windrow compost turner provides optimal temperature, humidity, and ventilation conditions to promote rapid propagation of beneficial microorganisms. This process not only eliminates pathogens and weed seeds but also converts complex organic matter into forms easily absorbed by plants.

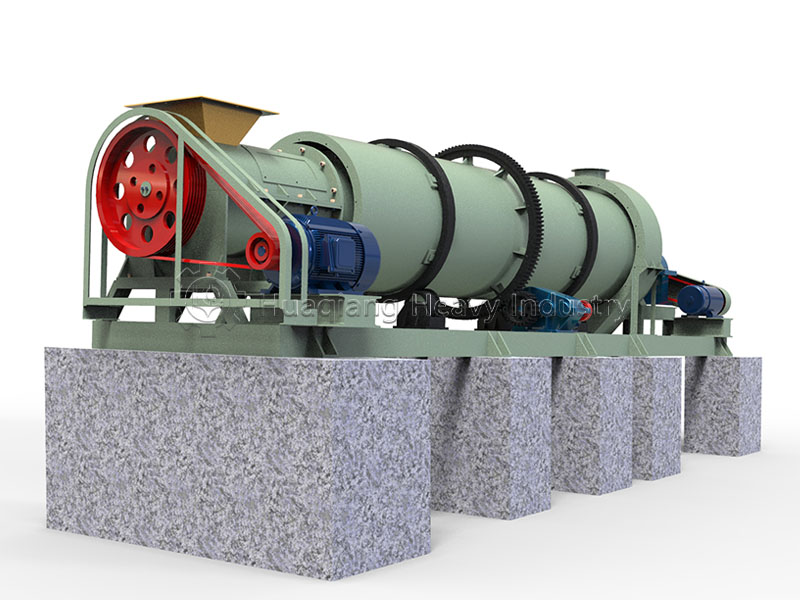

Drying and Cooling Stages

Dryers utilize gentle hot air circulation technology to effectively remove excess moisture without damaging nutrients. Subsequently, coolers gradually reduce granule temperature to prevent condensation and spoilage caused by temperature differentials.

Screening and Packaging

Vibratory screening equipment ensures only quality granules meeting specifications proceed to final packaging. Automated packaging systems then distribute finished products into various bagged or bulk formats according to market demands, facilitating transportation and sales.

Global Applications and Economic Benefits

In developed regions such as Europe, North America, and Australia, these integrated organic fertilizer production systems have gained widespread adoption. A farm in the Netherlands successfully transformed local food processing waste into high-quality organic fertilizer by introducing a complete equipment set, not only solving waste disposal challenges but also generating $1.5 million in additional annual revenue.

For developing countries, this technology holds equal importance. An agricultural cooperative in Punjab, India, after introducing a medium-sized production line, successfully converted rice straw and livestock manure into organic fertilizer, replacing 40% of chemical fertilizer use. Soil health significantly improved, and crop yields increased by 12%.

Smart Technology Empowering the Future

Modern fertilizer equipment is increasingly integrating with big data, and artificial intelligence technologies. Smart sensors monitor production parameters in real-time, cloud platforms analyze and optimize process formulas, and mobile applications enable farmers to remotely monitor production processes. At an innovative plant in Germany, this smart equipment has achieved 75% automated production, reducing energy consumption by 30% and increasing production efficiency by 40%.