In modern chemical, fertilizer, and building material production, the uniformity of material mixing directly determines the quality of the final product. The vertical disc mixer, with its unique vertical design concept, has completely transformed the working mode of traditional mixing equipment, providing an efficient solution for uniform mixing of powdered, granular, and pasty materials. This innovative equipment not only improves mixing efficiency but also brings unprecedented flexibility and reliability to the entire production line.

Working Principle: The Art of Vertical Mixing

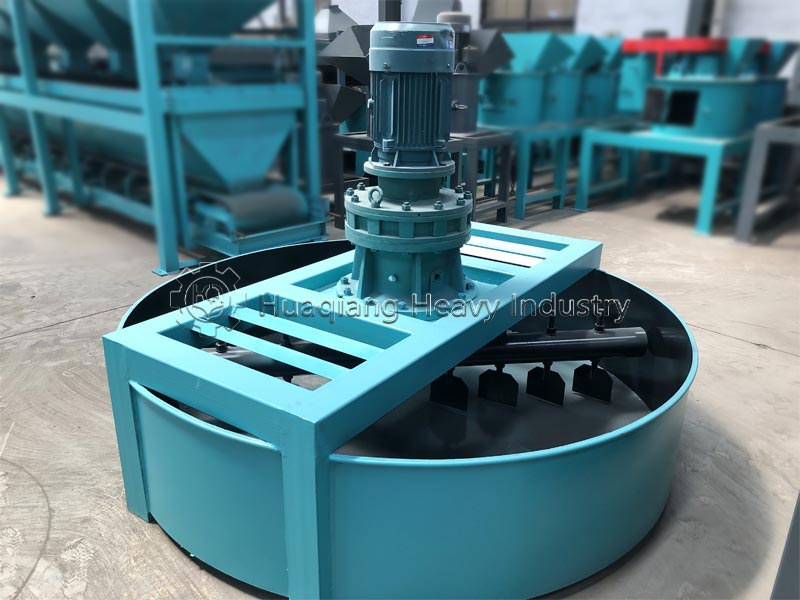

The core of the vertical disc mixer is a vertically installed disc-type mixing device. During operation, the mixing disc rotates at a specific angle and speed, lifting materials from the bottom upward while throwing them outward under centrifugal force. This vertical circulation motion creates a three-dimensional mixing effect, ensuring materials achieve a highly uniform state in a short time. The unique scraper design prevents material adhesion to the walls, while adjustable mixing blade angles accommodate the mixing needs of different materials.

Revolutionary Advantages of Vertical Design

Excellent Mixing Uniformity

The vertical mixing path creates a three-dimensional mixing effect, with mixing uniformity reaching over 95%, far exceeding the 80-85% of traditional horizontal mixers. The vertical circulation flow of materials eliminates stratification, ensuring consistency in each batch of products.

Efficient Mixing Speed

The unique design of the mixing disc reduces mixing time by 30-50%, with single batch processing requiring only 3-8 minutes. Efficient material flow paths reduce energy consumption while improving production efficiency.

Outstanding Cleaning Performance

The vertical structure design creates a dead-angle-free interior, making cleaning more convenient and thorough. Quickly replaceable mixing blades and detachable liner plates significantly reduce material changeover cleaning time, improving equipment utilization.

Flexible Space Layout

The vertical design occupies a small footprint, only 60-70% of horizontal mixers with equivalent capacity. This compact structure is particularly suitable for factory layouts with limited space, facilitating production line integration and automation transformation.

Low Maintenance Cost

Simple mechanical structure and the use of wear-resistant materials significantly reduce maintenance frequency and costs. Main bearings and transmission components are easy to inspect, with mean time between failures (MTBF) exceeding 10,000 hours.

Wide Material Adaptability

From fine powders to coarse granules, from low-density materials to high-viscosity slurries, vertical disc mixers can effectively handle all. By adjusting mixing parameters, they can adapt to the mixing needs of materials with different physical characteristics.

Comparison with Traditional Mixing Equipment

| Comparison Metric | Vertical Disc Mixer | Double Shaft Mixer |

| Mixing Uniformity | ≥95% | 85-90% |

| Mixing Time | 3-8 minutes | 5-12 minutes |

| Energy Consumption Level | Low | Medium |

| Floor Space | Small | Large |

| Cleaning Difficulty | Easy | Difficult |

| Maintenance Cost | Low | Medium |

Main Technical Specifications

Capacity Range

Standard models: 0.5-10 cubic meters

Custom models: Up to 20 cubic meters maximum

Suitable from small-scale testing to large-scale production

Power Configuration

Motor power: 5.5-75kW

Transmission method: Reducer direct coupling

Control method: Variable frequency speed regulation

Structure Materials

Shell: Carbon steel/Stainless steel 304/316L

Mixing blades: Wear-resistant alloy steel

Lining: Food grade/Wear-resistant liner plates

Performance Parameters

Mixing uniformity: ≥95%

Fill factor: 0.4-0.7

Noise level: ≤75dB

Wide Application Fields

With its excellent performance, vertical disc mixers have found wide applications in numerous industrial fields:

Fertilizer Production Industry

Chemical Raw Material Mixing

Feed Processing Field

Building Material Production

Food Additive Mixing

Pharmaceutical Raw Material Preparation

Environmental Material Production

New Energy Material Mixing

In fertilizer production lines, vertical disc mixers typically work in coordination with crushers, disc granulators, dryers, and packaging machines to form a complete production system. They are particularly suitable for mixing various fertilizer raw materials such as NPK compound fertilizers, organic fertilizers, and bio-fertilizers, ensuring uniform nutrient distribution and improving fertilizer quality.

Modern vertical disc mixers have achieved intelligent control, equipped with PLC automatic control systems that can store multiple formulas, monitor mixing process parameters in real time, and seamlessly integrate with other equipment in the production line to achieve fully automated production.