Zeolite-loaded fertilizer is a matrix-based composite slow-release fertilizer prepared based on the porous adsorption properties of natural zeolite. Its core principle is to load nutrients such as nitrogen, phosphorus, and potassium onto the pores and surface of zeolite, utilizing the adsorption and ion exchange properties of zeolite to slow down nutrient release. It features low cost, environmental friendliness, and long-lasting effects, making it an important category of traditional slow-release fertilizers.

Core Raw Material: Characteristics of Natural Zeolite

Zeolite is a hydrous aluminosilicate mineral with two key characteristics that make it an ideal fertilizer carrier:

Porous Structure and Strong Adsorption

Zeolite is filled with micron-sized pores and cavities, resulting in a large specific surface area. This allows it to firmly fix fertilizer solutions (such as urea solutions and potassium dihydrogen phosphate solutions) within the pores through physical adsorption, preventing rapid nutrient loss.

Cation Exchange Performance: Zeolite crystals contain a large number of exchangeable cations (such as Na⁺, Ca²⁺, K⁺), which can exchange with cations such as ammonium nitrogen (NH₄⁺) in fertilizers to form stable ion-bound states, further slowing down the nutrient release rate.

Preparation Process (Simplified Industrial Process): The production process of zeolite-loaded fertilizer is simple, requiring no complex equipment, and is suitable for small and medium-sized fertilizer plants. The core steps are as follows: Zeolite Pretreatment: Natural zeolite ore is crushed into 80-120 mesh fine powder and then roasted (at 300-500℃) to remove moisture and impurities from the pores, increasing porosity and enhancing adsorption and ion exchange capacity.

Nutrient Loading (Core Step)

Immersion Method: Immerse the pretreated zeolite powder in a prepared high-concentration fertilizer mixture (such as a mixture of urea + monoammonium phosphate + potassium chloride) for 2-4 hours at room temperature and pressure, stirring to ensure nutrients fully fill the zeolite pores.

Adsorption Equilibrium: Allow to stand for 12-24 hours to achieve adsorption-ion exchange equilibrium between the zeolite and fertilizer nutrients. Excess solution can be recycled.

Drying and Granulation: Dry the nutrient-loaded zeolite material to a moisture content ≤10%. Add a small amount of bentonite as a binder. Particles with a diameter of 2-4 mm are produced using a disc granulator or extrusion granulator. After sieving, the finished zeolite-loaded fertilizer is obtained.

III. Nutrient Release Mechanism The slow-release effect of zeolite-loaded fertilizer stems from the dual action of physical adsorption and ion exchange. The release process is divided into three stages, highly adapted to the nutrient requirements of crops:

Rapid Release Stage (1-7 days after fertilization):A small amount of readily available nutrients adsorbed on the zeolite surface dissolves rapidly upon contact with water, meeting the basic nutrient needs of crop seedlings.

Slow Release Stage (7-60 days after fertilization): Nutrients adsorbed within the zeolite pores gradually dissolve and diffuse into the soil as soil moisture permeates. Simultaneously, hydrogen ions (H⁺) in the soil exchange with cations such as ammonium nitrogen bound to the zeolite, continuously releasing effective nutrients to match the peak nutrient requirements of crops during their vigorous growth period.

Long-Lasting Release Stage (60-120 days after fertilization):Nutrients stably bound within the zeolite lattice are continuously released through the slow decomposition by soil microorganisms and ion exchange, preventing nutrient deficiency and premature senescence in crops later stages. IV. Core Advantages

Low Cost, High Cost-Effectiveness:Natural zeolite is abundant and inexpensive. Its preparation process requires no coating or chemical synthesis, resulting in production costs far lower than polymer-coated controlled-release fertilizers and close to ordinary compound fertilizers, making it suitable for large-scale application in field crops.

High Nutrient Utilization, Reduced Pollution:Compared to ordinary chemical fertilizers, zeolite-based fertilizers can increase nitrogen utilization by 20%-30%, effectively reducing nitrogen leaching and ammonia volatilization losses, and lowering the risk of soil compaction and eutrophication.

Soil Improvement, Two Benefits in One: Zeolite itself contains trace elements such as silicon, aluminum, and calcium, and its porous structure improves soil aeration and water and fertilizer retention capacity. Long-term application can optimize soil aggregate structure, making it particularly suitable for sandy and infertile soils.

Flexible Application, Strong Compatibility:It can be applied as a base fertilizer in a single application, or as a top dressing in furrows or holes; it can be used alone or mixed with organic fertilizers and microbial fertilizers without producing antagonistic reactions.

Flexible Application, Strong Compatibility:It can be applied as a base fertilizer in a single application, or as a top dressing in furrows or holes; it can be used alone or mixed with organic fertilizers and microbial fertilizers without producing antagonistic reactions. V. Product Types and Applicable Scenarios

Main Product Types

Zeolite Nitrogen Fertilizer: Primarily loaded with urea and ammonium chloride, featuring slow-release nitrogen, suitable for field crops with high nitrogen requirements such as wheat and corn.

Zeolite Compound Fertilizer: Loaded with nitrogen, phosphorus, and potassium, suitable for the full nutrient needs of fruits, vegetables, cotton, and other cash crops.

Zeolite Micronutrient Fertilizer: Loaded with macronutrients, supplemented with micronutrients such as zinc, iron, and boron to address nutrient deficiencies in crops.

Applicable Scenarios

Preferred: Field grain crops (wheat, corn, rice), field cash crops (cotton, soybeans). Significantly reduces fertilization costs for large-scale planting.

Suitable Soil: Sandy soil (enhances fertilizer retention capacity), infertile soil (improves soil structure), greenhouse soil (reduces salt accumulation).

Precautions for Use

The nutrient release rate of zeolite-loaded fertilizer is greatly affected by soil moisture. In arid areas, irrigation is necessary to fully realize the slow-release effect.

It is not suitable for use as a foliar fertilizer because its granular form makes it difficult for leaves to absorb, and its nutrient release rate cannot match the rapid-acting requirements of foliar fertilization.

When storing, it should be placed in a dry, well-ventilated place to avoid moisture and clumping, which would affect its application effect.

From Mineral Carrier to Finished Granule: A Modern Production Path

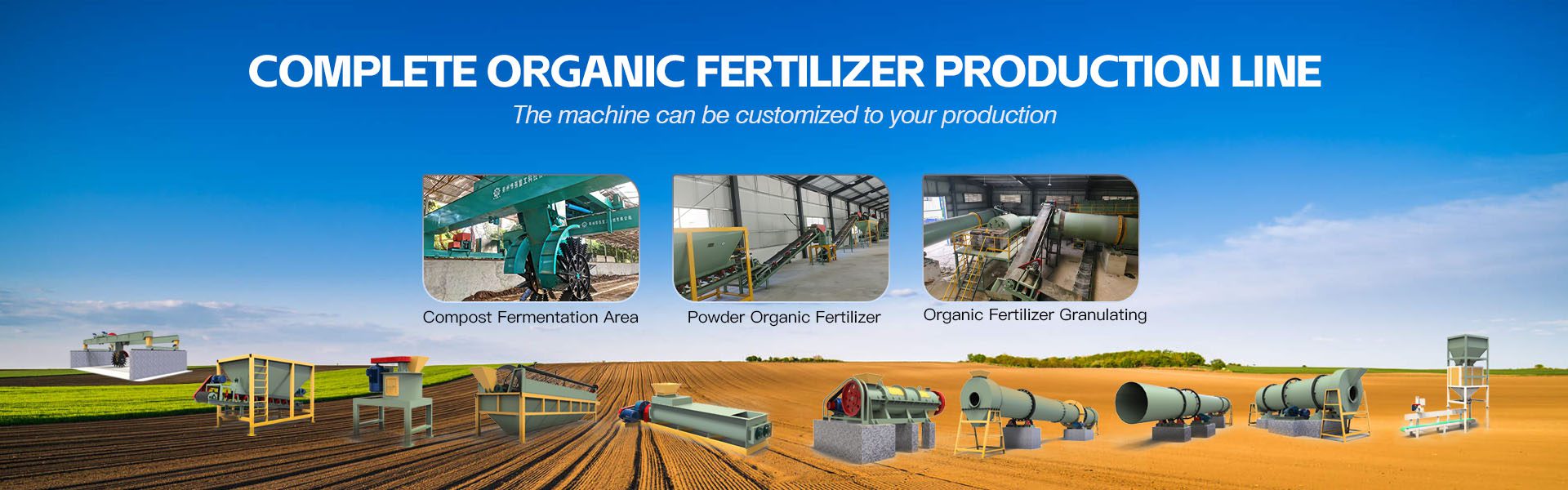

The production of zeolite-loaded slow-release fertilizers demonstrates a specialized niche within broader fertilizer granulation processes. To manufacture this product at scale, the nutrient-saturated zeolite powder must be integrated into a formal production system. This could be a dedicated line or incorporated into a modified segment of a standard npk fertilizer production line. The process involves precise mixing to ensure uniform nutrient distribution on the zeolite matrix before entering the granulation stage.

The granulation of this composite material requires appropriate fertilizer granulator equipment. A disc granulator for shaping is often suitable, forming part of a disc granulation production line. This contrasts with the technology used for conventional compound fertilizers, which might utilize a double roller press granulator in a roller press granulator production line for dry compaction. The ability to utilize standard fertilizer granulation processes and equipment, such as the disc granulator machine, makes zeolite fertilizer a viable and scalable slow-release option, bridging the gap between innovative material science and established, efficient manufacturing to deliver cost-effective, soil-enhancing fertilizers.