Where Nature Meets Technology

The bio-organic fertilizer production line operates like a magical “microbial factory,” transforming agricultural waste into vitality-rich black gold. This system brilliantly combines nature’s decomposition wisdom with modern industrial precision, turning invisible microorganisms into “star workers” on the fertilizer production line.

Unlike traditional composting, each fermentation tank here features smart monitoring systems that track temperature, humidity and oxygen levels in real-time, creating optimal working conditions for microbes. This precision management reduces fermentation cycles by 40% while increasing beneficial microbe survival rates over threefold.

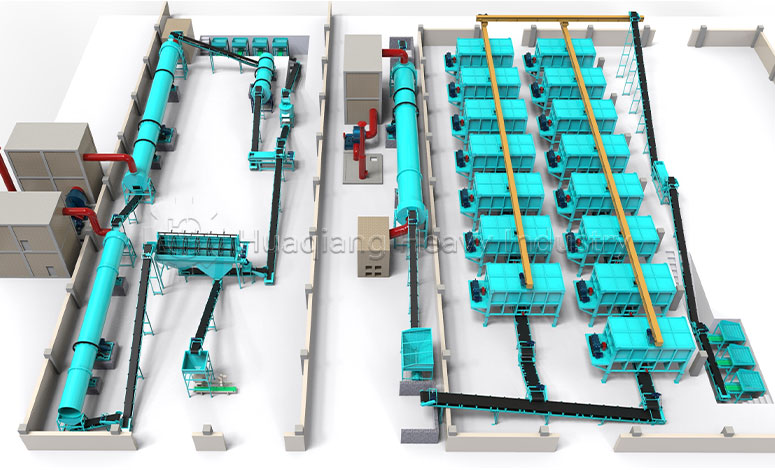

Symphony of Core Equipment

Building an efficient bio-organic fertilizer line requires a well-orchestrated “equipment ensemble”:

Pre-treatment unit: Crushers and sorters act as the overture, processing raw materials into uniform fragments

Fermentation core: Intelligent turners conduct like maestros, regulating aeration and moisture

Post-treatment: Fine grinders and granulators transform matured materials into standardized products

Microbe inoculation: Functions as precise tuners, infusing fertilizers with active microbial communities

Modern fermentation tanks deserve special mention – featuring double-layer insulation with built-in ventilation ducts, they maintain ideal 55-65°C temperatures even in winter, ensuring year-round microbial efficiency.

Green Revolution for Soil Health

The unique value of bio-organic fertilizers lies in bringing life to soil:

- Premium products contain 200+ million active microbes per gram

- Organic matter content stabilizes at 45-60%

- Rich in amino acids, humic acids and other bioactive substances

- Neutral pH gently protects soil balance

These “living fertilizers” not only provide nutrition but rebuild soil micro-ecosystems, solving modern agricultural challenges like continuous cropping obstacles. Data shows after three years of consistent use, soil porosity increases 35% and water retention improves 50%, truly realizing the sustainable agriculture vision of “storing grain in the soil.”