Modern fertilizer production requires a complex combination of general-purpose equipment and specialized machinery. Understanding this equipment is crucial for anyone involved in agricultural manufacturing or considering entering the fertilizer industry.

General Equipment in Fertilizer Production

All fertilizer production lines share certain fundamental equipment that handles the basic processing stages:

| Equipment | Function | Application Stage |

| Crusher | Reduces raw material size for processing | Initial processing |

| Mixer | Uniformly blends different components | Formulation |

| Granulator | Forms powder mixtures into granules | Granulation |

| Dryer | Reduces moisture content | Post-granulation |

| Cooler | Lowers temperature after drying | Post-drying |

| Screening Machine | Separates granules by size | Quality control |

| Coating Machine | Applies protective or functional coatings | Final processing |

| Packaging Machine | Packages final product for distribution | Final stage |

Specialized Fertilizer Equipment

Beyond general equipment, specialized fertilizer production requires additional machinery tailored to specific product types:

| Specialized Equipment | Function | Application |

| Compound Fertilizer Granulator | Produces NPK fertilizers with precise nutrient ratios | Compound fertilizers |

| Organic Fertilizer Fermentation Equipment | Facilitates aerobic decomposition of organic matter | Organic fertilizers |

| Slow-Release Coating System | Applies polymer coatings for controlled nutrient release | Slow-release fertilizers |

| Urea Melting System | Handles molten urea for specific formulations | Urea-based fertilizers |

| Biofertilizer Inoculation System | Introduces beneficial microorganisms | Biofertilizers |

| Liquid Fertilizer Reactor | Produces and blends liquid formulations | Liquid fertilizers |

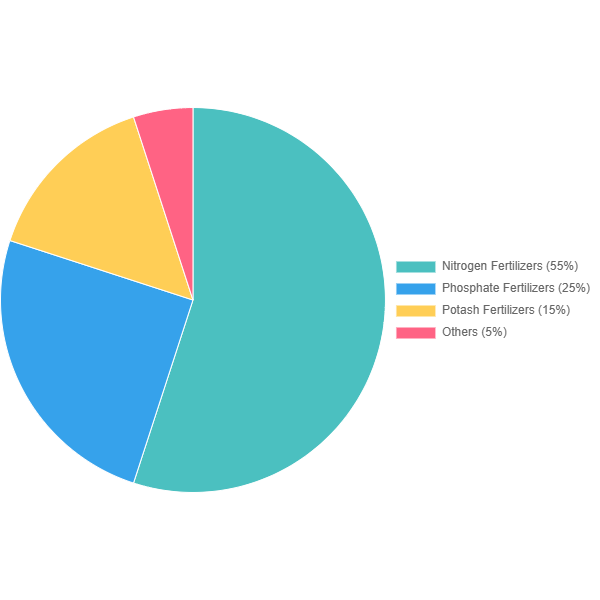

Global Fertilizer Production by Type

Selecting the Right Equipment

Choosing appropriate equipment depends on several factors:

- Production capacity:Small (1-5 tons/hour), medium (5-20 tons/hour), or large-scale (20+ tons/hour)

- Fertilizer type:Organic, inorganic, compound, or specialty fertilizers

- Automation level:Manual, semi-automatic, or fully automatic systems

- Budget:Initial investment versus long-term operational costs

Modern fertilizer production lines increasingly incorporate smart technologies such as IoT sensors for real-time monitoring and AI-driven optimization systems to improve efficiency and product consistency.