Building a mushroom residue organic fertilizer plant requires comprehensive consideration of local resources, market capacity, and coverage radius. The annual output of the construction scale is generally 40,000 to 300,000 tons. Small factories should produce 10,000 to 40,000 tons per year, medium-sized factories should produce 50,000 to 80,000 tons per year, and large factories should produce 90,000 to 150,000 tons per year.

The formulation of the plan for building a mushroom residue organic fertilizer plant may follow the following principles: resource characteristics, soil conditions, local main species, plant structure, site conditions, etc. Huaqiang Heavy Industry mainly analyzes the following points here:

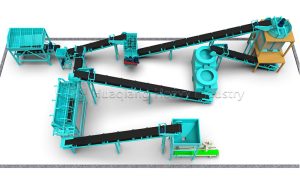

1. Characteristics of organic fertilizer raw materials. Mushroom residue has a high water content and a humid growth environment. The construction of a mushroom residue organic fertilizer plant requires a dryer and a cooler, and a suitable granulator is selected according to the water content of the raw materials.

2. Finished product demand. Some farms build their own mushroom residue organic fertilizer plants for their own use, and for cost considerations, they can build a powdered organic fertilizer plant. Some mushroom farms have large outputs, and the raw materials are sufficient to produce a large amount of organic fertilizer for sale. In this case, the manufacturer can build a granular organic fertilizer plant by itself.

3. Site conditions. Since mushroom residue needs to be composted and fermented to be made into organic fertilizer, it takes up space. When manufacturers build their own mushroom residue organic fertilizer plants, they must also take the fermentation site into consideration.

In general, there are many factors to consider when building a mushroom residue organic fertilizer plant. The key is to clarify factors such as raw material output, site size, and investment amount, and choose a mushroom residue organic fertilizer plant construction plan that suits you based on these factors.