Since the 13th Five-Year Plan, one of the main tracks of agriculture is to replace chemical fertilizer with organic fertilizer. Especially the first batch of people who smelled this business opportunity, took advantage of the national promotion of this policy, opened an organic fertilizer production line, and made a lot of money. Until today, this is also a good thing worth doing. From the perspective of circular economy, a large amount of waste generated in the production of other industries can be used in the planting industry, such as livestock and poultry manure in the breeding industry, agricultural orange stalks, etc., and waste from the food processing industry such as mushroom residue, cassava residue, sugarcane residue, wine lees, etc., mushroom sticks, mushroom residue, sugarcane residue, etc., are all suitable raw materials for organic fertilizer, waste recycling, circular economy, and benefits the country and the people.

Due to the guidance of national policies and environmental protection, the opening of an organic fertilizer production line will be a rigid demand for a long time, especially for various types of breeding enterprises. The treatment of livestock and poultry manure is best to establish an organic fertilizer production line.

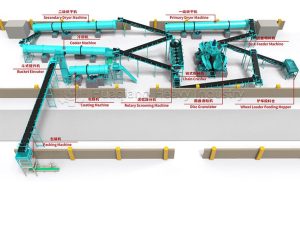

For the opening of an organic fertilizer plant, the most important thing is to purchase equipment for making organic fertilizer.

The basic principle of the organic fertilizer production line is to mix organic materials such as solid waste with wood chaff, straw shreds, etc., and carry out natural fermentation or aerobic fermentation with the addition of microorganisms to convert organic matter into stable humus. Different treatment methods and scales have slightly different methods.