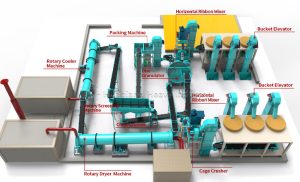

The organic fertilizer production process can be clearly divided into several main steps. The following is a detailed process flow:

First,Raw material preparation and pretreatment

1.Raw material collection: The main raw materials for organic fertilizer production include livestock and poultry manure, crop straw, domestic garbage, etc. The raw materials are collected regularly from farms, farmlands, etc. by special vehicles to ensure the freshness of the raw materials and reduce pollution during transportation.

2.Pretreatment: After collection, the raw materials need to be pretreated, including cleaning, screening, crushing and other steps to remove impurities and adjust the particle size of the raw materials for subsequent processing.

Second,Fermentation and composting

1. Ingredients: According to the type and nature of the raw materials, the raw materials are mixed in a certain proportion, and an appropriate amount of fermentation bacteria and trace elements are added to promote the fermentation process.

2. Fermentation: The raw materials are aerobically fermented in the fermentation workshop, and the raw materials are regularly turned by the compost turning machine to ensure the uniformity and sufficiency of the fermentation. During the fermentation process, the fermentation temperature is controlled between 50℃ and 65℃, and the temperature and humidity changes during the fermentation process are monitored.

3. Composting: After a period of fermentation, the raw materials gradually become decomposed, the color becomes darker, and the odor decreases. At this time, the raw materials need to be further decomposed to ensure the quality and stability of the organic fertilizer.

Third,Post-processing and packaging

1.Crushing and screening: The decomposed raw materials are crushed by a crusher and screened by a screening machine to remove large particles and impurities.

2.Blending and mixing: According to the needs and formula of the product, the crushed raw materials are mixed with an appropriate amount of additives to adjust the nutritional content and properties of the organic fertilizer.

3.Drying and cooling: The mixed raw materials are dried by a dryer to remove the moisture, and then cooled by a cooler for subsequent packaging and storage.

4.Packaging and warehousing: The organic fertilizer after drying and cooling is quantitatively packaged by an automatic packaging machine and then sent to the finished product warehouse for storage and sales.