On the stage of modern agriculture, the npk blending fertilizer production line acts like an “agricultural nutritionist” skilled in precise nutrient formulation, able to customize various “nutritional packages” according to crop needs. This physical mixing method of fertilizer production line perfectly avoids the high energy consumption of chemical synthesis while creating endless formulation possibilities.

The Magic of Flexible Formulations

Traditional compound fertilizer production is like preparing a fixed menu, while the npk blending fertilizer production line resembles a chef with unlimited creativity. It can adjust the ratios of nitrogen, phosphorus, potassium and other elements according to different crops and growth stages. Raw materials like urea, diammonium phosphate, and potassium sulfate act as seasonings, mixed in precise measurements to create the most suitable “nutritional feast” for current agricultural needs. This flexibility truly realizes the scientific concept of “fertilizing according to soil and crop requirements.”

The core advantage of npk blending fertilizer production lines lies in their formulation flexibility, enabling quick response to market demands for different nutrient ratios and providing strong support for precision agriculture.

The Symphony of Precision Operation

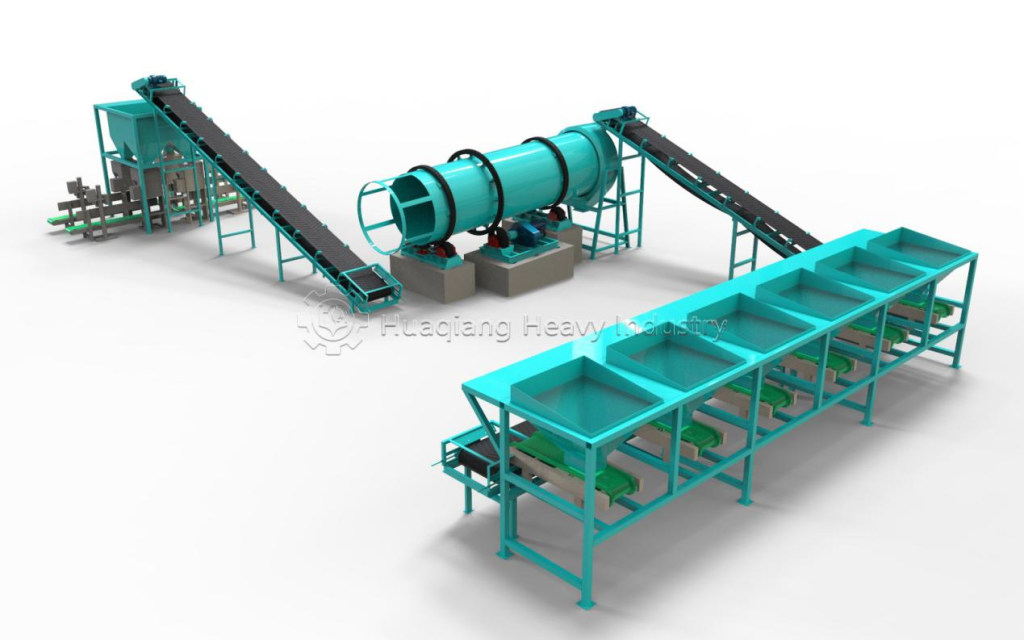

Main Equipment Components:

- Raw material storage and transportation system:Ensures stable supply of various materials

- High-precision measuring equipment:Strictly controls the proportion of each element

- Efficient mixer:Uniformly blends all ingredients

- Cooling and screening system:Regulates temperature and ensures uniform particles

- Automated packaging line:Completes product packaging

Entering a npk blending fertilizer production plant is like listening to a precise industrial symphony. The raw material storage and transportation system forms the steady bass line, ensuring stable supply of various materials; high-precision measuring equipment acts like a metronome, strictly controlling the proportion of each element; efficient mixers become the passionate main melody, uniformly blending all ingredients. The cooling and screening system provides a soothing interlude, while the automated packaging line plays the perfect finale. The PLC or DCS control system serves as the conductor, ensuring harmony in every section.

Intelligent Quality Assurance

The most commendable aspect of modern npk blending fertilizer production lines is their intelligent control systems. From material ratios to mixing time, from temperature control to packaging measurements, every parameter is precisely monitored and adjusted. This intelligence not only guarantees product quality consistency but also significantly improves production efficiency. Operators simply input formulation parameters, and the entire system automatically completes the whole process from raw materials to finished products, truly achieving “one-click” intelligent production.

The Philosophy of Eco-Efficient Production

Compared to traditional compound fertilizer production methods, npk blending fertilizer production lines demonstrate clear environmental advantages. They don’t require high-temperature, high-pressure chemical reactions, greatly reducing energy consumption; the physical mixing approach also minimizes waste gas and water emissions. This “gentle” production process delivers “powerful” fertilizer effects, perfectly illustrating modern agriculture’s dual pursuit of efficiency and environmental protection.

The npk blending fertilizer production line is redefining modern fertilizer production standards with its unique flexibility, precision, and eco-friendliness, providing strong technical support for the development of precision agriculture.