In the fertilizer production line, chemical, and food industries, the disc granulation line acts like an elegant “spherical artist,” transforming powders into perfect granules through rotational magic. What makes this unique granulation method so captivating? Let’s explore its secrets.

Core Advantages

- Efficient granulation:Utilizes centrifugal force and material friction for rapid granulation

- Uniform particles:Highly consistent granule size and shape

- Strong material adaptability:Handles various types of raw materials

- Simple operation:Straightforward structure with low maintenance costs

- Low energy consumption:More energy-efficient than other granulation processes

The Art of Rotational Granulation

The core charm of the disc granulator lies in its simple yet efficient working principle. Imagine a large tilted rotating disc where powder materials, under the dual action of centrifugal force and inter-particle friction, gradually form uniform spheres like dancers performing an elegant waltz. This “gentle” granulation method avoids structural damage that high-pressure extrusion might cause, making it particularly suitable for products requiring granule integrity.

The Efficient and Versatile Performer

The disc granulation line can be considered the “all-rounder” of the industrial world. It effortlessly handles various raw materials—from fertilizer ingredients to food additives—demonstrating remarkable adaptability. With fast granulation speed and high efficiency, it maintains exceptional consistency in granule size and shape, a rare balance in industrial production. More impressively, compared to other granulation processes, its energy consumption is significantly lower, truly achieving the perfect combination of efficiency and energy savings.

Disc granulation technology perfectly balances production efficiency with product quality, becoming the preferred granulation solution for numerous industries.

Intelligent Quality Assurance

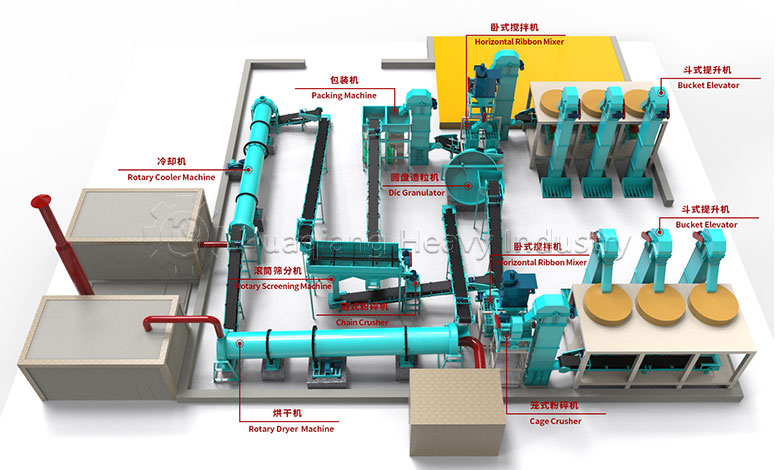

Modern disc granulation production lines are no longer simple mechanical devices but “thinkers” equipped with intelligent control systems. From material ratios to granulation conditions, from drying temperatures to finished product packaging, every parameter is precisely monitored. This intelligence not only ensures product quality consistency but also greatly simplifies operational procedures—operators need only set parameters, and the system automatically completes the entire production process, minimizing human error.

The Economical Industrial Choice

The disc granulator’s structural design embodies the philosophy of “less is more.” Simple mechanical construction translates to lower maintenance costs and longer service life, undoubtedly significant benefits for production enterprises. Meanwhile, low energy consumption and stable output make this production line an ideal choice balancing economic benefits with environmental requirements.

In modern industry’s pursuit of efficiency and quality, the disc granulation line, with its unique granulation method, flexible adaptability, and stable output quality, is becoming the preferred granulation solution for an increasing number of industries.