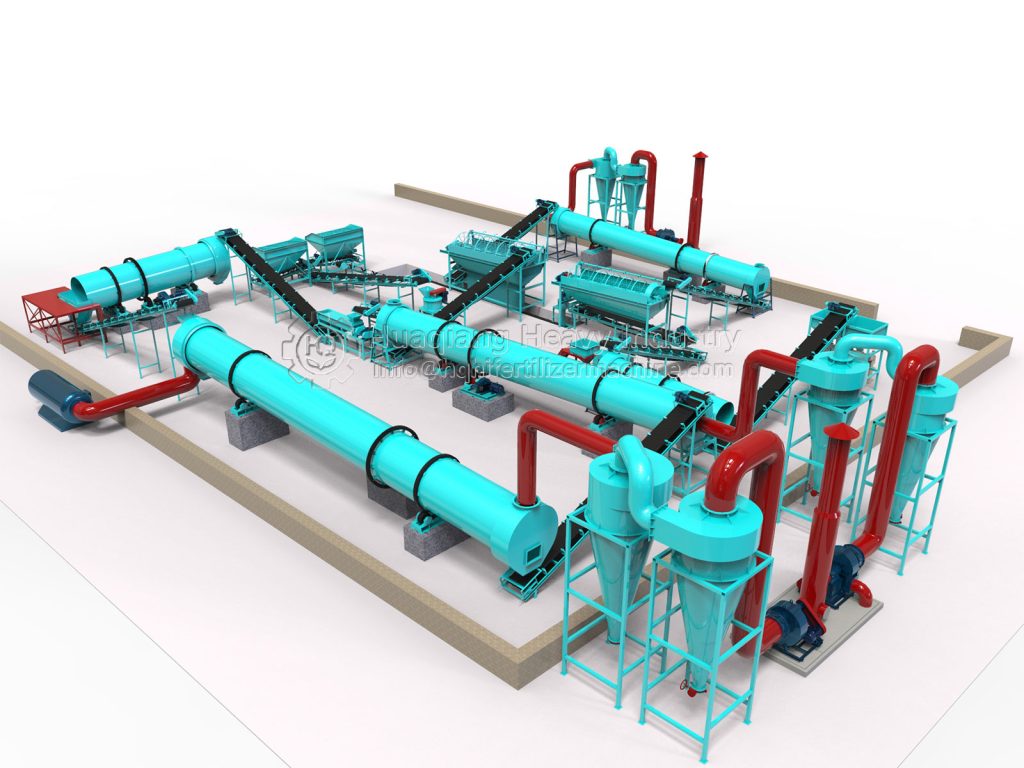

In modern fertilizer industry, the rotary drum granulation line acts like a master magician, transforming various raw materials into uniform, perfect granules. Whether for compound fertilizers, bio-fertilizers or controlled-release fertilizers, this system handles all with ease, making it the preferred choice for large-scale production.

“From cold granulation to hot processes – one system meets diverse production needs”

Intelligent Feeding & Steam Conditioning

Precision Batching System

According to preset formula ratios, various raw materials are fed into the drum at a constant rate through smart metering systems. Simultaneously, saturated steam is precisely injected into the material bed. This “steam SPA” enables granulation at lower moisture content, not only raising material temperature but also reducing drying load by 30-40%.

Three Advantages of Steam Conditioning:

- Energy Efficiency: Reduces subsequent drying energy consumption

- Quality Enhancement: Increases granule strength by 25%

- Process Flexibility: Allows steam quantity adjustment as needed

The All-Round Production Specialist

The true value of rotary drum granulation lines lies in their remarkable adaptability:

NPK Compound Fertilizer Bio-Organic Fertilizer Controlled-Release Fertilizer High-Concentration Formula Medium-Low Concentration Formula

With simple parameter adjustments, the same equipment can meet different formula and process requirements, greatly improving equipment utilization and ROI.

The Art of Liquid Phase Adjustment

Based on real-time monitoring of pelletizing rate, the system intelligently sprays appropriate amounts of water or fertilizer solution to maintain optimal liquid phase conditions. This dynamic adjustment mechanism ensures:

- Pelletizing rate stabilized above 75%

- Uniform granule size

- Smooth and rounded surfaces

- Even nutrient distribution

From raw materials to finished products, the rotary drum granulation line combines technology and wisdom perfectly, providing continuous efficient fertilizer solutions for modern agriculture.