In modern agricultural production, NPK compound fertilizer is like a nutritional package for plants, and the drum granulation process is the careful cooking of this package. Let’s step into this wonderful world that transforms basic fertilizers into efficient granules.

“From raw material screening to granule formation, each step embodies the wisdom of agricultural technology”

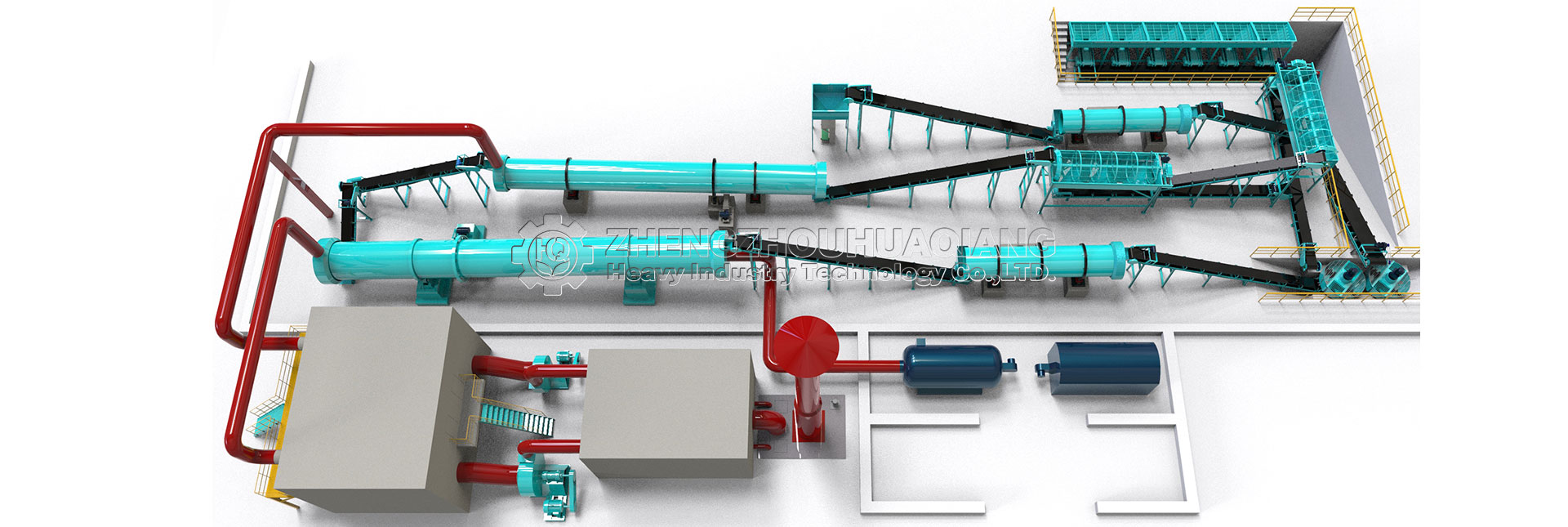

Meticulous Raw Material Preparation

Step 1: Raw Material Pretreatment

Each basic fertilizer (N, P, K) undergoes independent screening and crushing to ensure uniform particle size. The screened materials are accurately sent to corresponding storage bins, much like a chef preparing ingredients before cooking.

Precision Batching and Mixing

Step 2: Intelligent Proportioning

Through automatic measuring equipment, various basic fertilizers are precisely mixed according to formula ratios. Meanwhile, the system recycles unqualified materials back into the mixing process, with this circular design achieving over 95% raw material utilization rate.

The Magical Granulation Process

Step 3: Steam Conditioning & Forming

When the mixed materials enter the rotary drum granulator, saturated steam passes through the material layer from below, like giving the materials a “steam SPA”. When necessary, a small amount of water or fertilizer solution is added. Under the mechanical force generated by the drum rotation, the materials gradually agglomerate into balls.

Three Advantages of Drum Granulation:

- Precise Temperature Control: Steam system maintains optimal reaction temperature

- Flexible Liquid Phase Adjustment: Moisture content can be adjusted as needed

- High Granule Strength: Compression from drum rotation forms dense particles

Post-processing and Recycling

The initially formed granules undergo drying, screening, and cooling before being packaged and stored. The screened powder and substandard particles are crushed and reintroduced into the system. This closed-loop design is both economical and environmentally friendly.

From single fertilizers to compound granules, the NPK fertilizer production line is like a precision ecosystem, with each link reflecting modern industry’s relentless pursuit of efficiency and quality.