In modern agricultural production, the quality of compound fertilizers directly affects crop yields and soil health. The segregation of components in multi-component mixed products has long been a technical challenge for fertilizer manufacturers. Excitingly, advanced granulation technology has successfully solved this problem across various production systems! This process is fundamental to both a standard npk fertilizer production line and sophisticated bio organic fertilizer production, converting raw materials into uniform granules to prevent component segregation. Whether it’s a complex organic fertilizer production line or a simpler bulk blending fertilizer line, this technology ensures quality stability. It boasts wide raw material adaptability, achieving ideal granulation effects for compound fertilizers, pharmaceuticals, chemical materials, or feed, fundamentally ensuring product consistency from batch to batch.

Why Choose Granulation Technology?

The most notable advantage of granulation technology lies in its excellent granulation rate, enabling the production of various concentrations and types of fertilizer products. From organic-inorganic compound fertilizers to biofertilizers, from high-concentration compound fertilizers to special functional fertilizers, an advanced granulation production line can handle them all with ease.

Imagine your production line could flexibly switch between producing different fertilizer formulations without worrying about component segregation or quality fluctuations—this is exactly the transformative advantage brought by granulation technology!

What Key Equipment Does a Complete NPK Fertilizer Production Line Include?

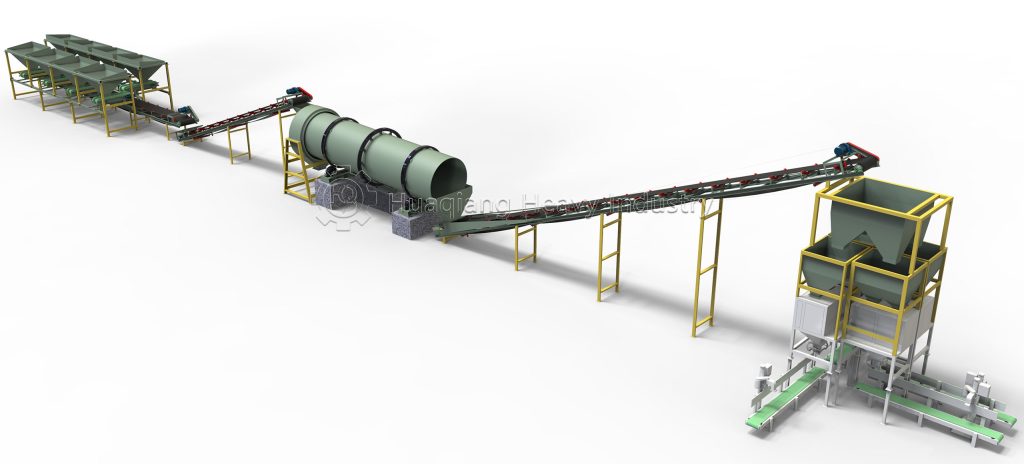

A complete modern NPK fertilizer production line is a perfect combination of multiple precision equipment:

- Automatic batching machine– Precisely controls various material ratios

- Belt conveyor– Achieves efficient and smooth material transportation

- Mixer– Ensures thorough and uniform mixing of raw materials

- Crusher– Processes materials to ideal particle size

- Rotary drum granulator– Core granulation equipment for high-quality granule formation

- Dryer– Removes excess moisture from granules

- Cooler– Cools granules for subsequent processing

- Screening machine– Grades and selects qualified granules

- Coating machine– Enhances granule performance and prevents caking

- Automatic packing machine– Achieves efficient and precise product packaging

This highly automated production line not only significantly improves production efficiency but, more importantly, ensures every fertilizer granule meets strict quality standards. From raw material processing to finished product packaging, every step is carefully designed to guarantee product consistency and reliability.

For fertilizer manufacturers pursuing excellence, investing in such a modern NPK fertilizer production line is undoubtedly a wise choice to enhance product competitiveness and win market share!