In modern agriculture, NPK compound fertilizers, precisely replenishing nitrogen, phosphorus, and potassium, have become a crucial “nutritional meal” for crop growth. Are you curious about the operating principles of an NPK fertilizer production line that precisely adjusts nutrients on demand? And what equipment supports its efficient production?

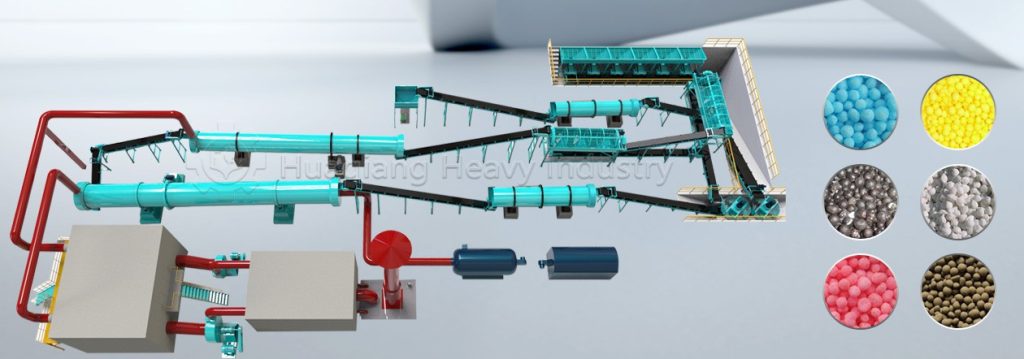

The core of an NPK fertilizer production line is “precise proportioning + efficient granulation.” At the raw material stage, basic ingredients such as phosphate rock, urea, and potassium chloride are first crushed into a fine powder by a crusher. Then, an intelligent batching system precisely weighs the ingredients according to crop needs. For example, the urea ratio can be adjusted to address rice’s high nitrogen requirements, while the potassium chloride dosage can be increased to address fruit trees’ high potassium requirements.The mixer thoroughly blends the formulated raw materials to ensure uniform nutrient content in each fertilizer pellet. The materials then enter the granulator, where they are formed into uniformly sized pellets through extrusion or drum granulation. After pellet formation, a dryer removes excess moisture, a cooler quickly solidifies the pellets, and a sieving machine removes unqualified pellets for reprocessing to ensure final product quality.

In addition to the core production equipment, the NPK production line also requires specialized auxiliary equipment. The coating machine coats the pellets with a waterproof, anti-caking film, extending the fertilizer’s shelf life. The quantitative packaging machine accurately packages the fertilizer into 25 kg, 50 kg, and other sizes, depending on demand, for easy transportation and use. Cyclone dust collector removal equipment collects dust generated during the production process, protecting worker health and complying with environmental standards. These devices work in conjunction with the core production line, ensuring efficient and environmentally friendly NPK fertilizer production, from raw materials to finished product.

Today, global agriculture is increasingly demanding precision fertilization. NPK fertilizer production lines can flexibly adjust nutrient ratios to meet the needs of different crops and soils.