The choice of granulator and its environmental compliance further differentiate NPK fertilizers from bulk mixed fertilizers, impacting production efficiency and sustainability.

Selecting the appropriate fertilizer granulator is crucial for optimizing both production efficiency and environmental performance across different fertilizer manufacturing systems. In an NPK fertilizer production line, the integration of a high-quality fertilizer mixer machine ensures homogeneous nutrient distribution before granulation, which is essential for meeting precise chemical specifications. Meanwhile, in organic fertilizer production line configurations, granulator choice directly impacts product quality and processing efficiency.

The emergence of bio organic fertilizer production adds another dimension to equipment selection, where granulators must preserve microbial viability while achieving proper pellet formation. Environmental compliance begins with proper equipment selection that minimizes dust emissions, optimizes energy consumption, and ensures consistent product quality. The synergy between mixing and granulation technologies across these production lines represents the foundation of sustainable fertilizer manufacturing that meets both agricultural needs and regulatory standards.

The selection of an appropriate NPK fertilizer granulator is a critical decision that shapes the entire NPK production line. This choice directly influences particle size uniformity, nutrient homogeneity, and dissolution rates—key factors that distinguish premium NPK fertilizers from simple bulk blends.

Within the comprehensive NPK fertilizer production process, the granulation stage serves as the quality cornerstone. Advanced granulators enable precise control over the physical characteristics of the final product while ensuring compliance with stringent environmental regulations regarding dust emissions and resource utilization.

Environmental considerations extend beyond emissions control. Modern NPK fertilizer production process designs incorporate resource recovery systems that minimize waste and energy consumption, aligning industrial operations with circular economy principles. This holistic approach to sustainability enhances market competitiveness while reducing ecological footprints.

Traditional Bulk Blending

Simple physical mixing of raw materials with limited nutrient precision and higher segregation potential during handling and application.

Modern NPK Granulation

Chemical bonding through granulation creates homogeneous particles with precise nutrient ratios, reduced dust, and improved handling properties.

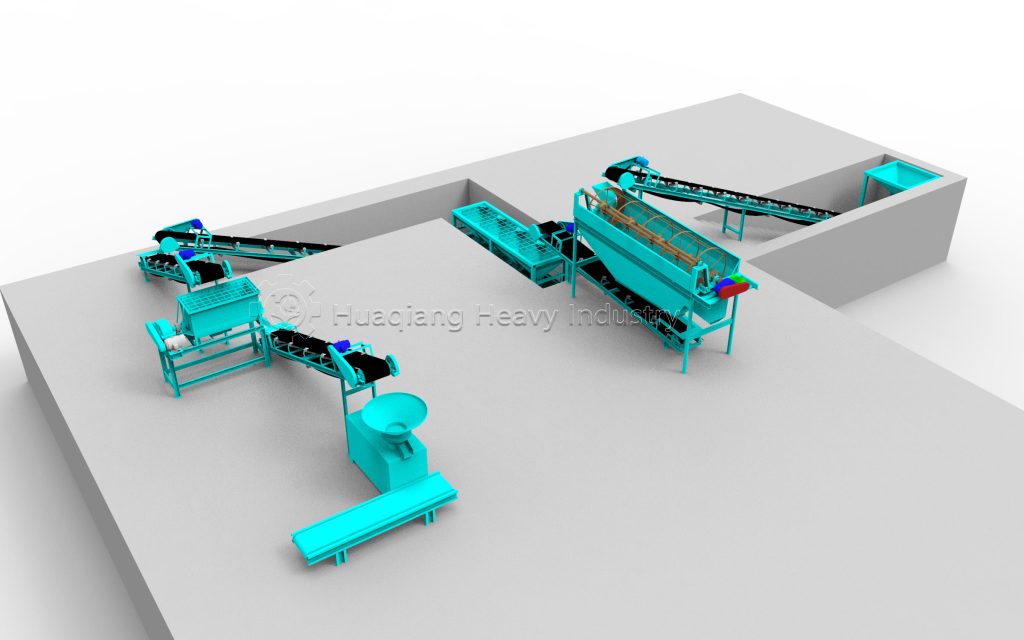

NPK Fertilizer Production Process Flow

1.Raw Material Preparation & Mixing

2.Granulation Process (60-100°C)

3.Drying & Cooling

4.Screening & Packaging

Both granulation systems must be integrated seamlessly into the broader NPK production line, with careful consideration of upstream mixing and downstream drying processes. The NPK fertilizer granulator serves as the heart of the operation, determining not only production efficiency but also the final product quality that reaches farmers.