Exploring how modern NPK fertilizer manufacturing processes provide precise and efficient nutritional solutions for global agriculture through automation and intelligent technology

Exemplar of Intelligent Manufacturing: The Revolution in NPK Fertilizer Production Technology

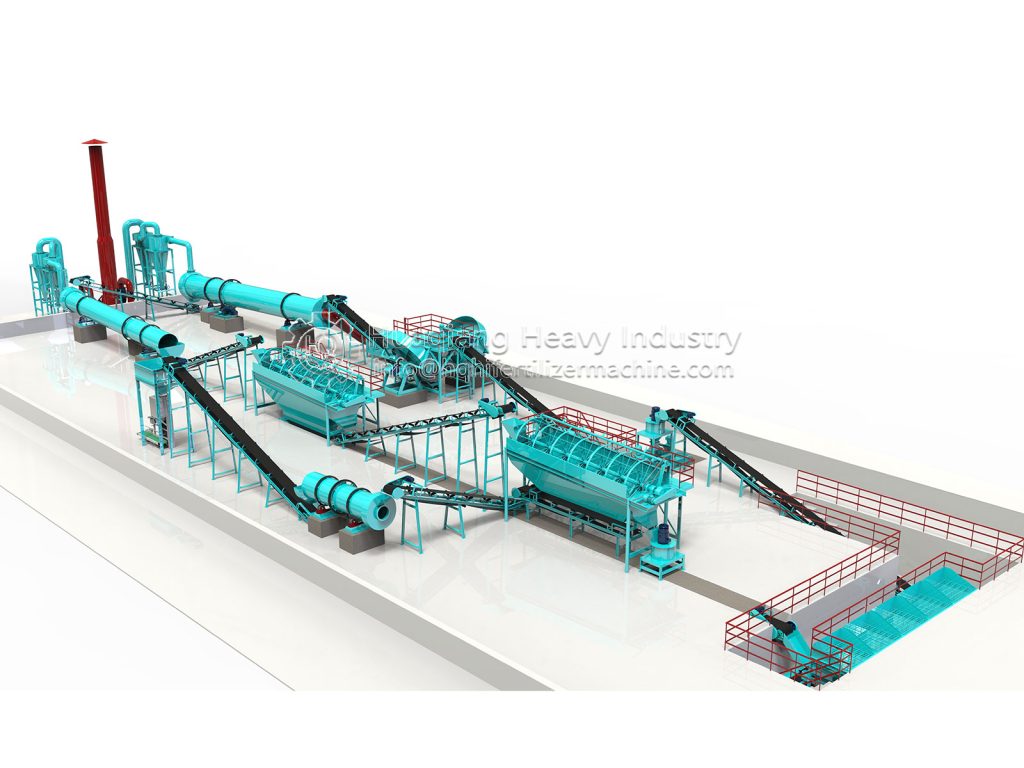

In today’s era of efficiency and precision, NPK fertilizer production technology is undergoing an unprecedented technological revolution. Modern manufacturing within an NPK fertilizer production line represents a complex systematic engineering project integrating automation, intelligence, and precision, far surpassing simple mixing and granulation.

The process begins with precise formulation in advanced fertilizer mixer machine units, followed by granulation through sophisticated equipment like the disc granulator and other types of fertilizer granulator technology. This systematic approach extends to bio organic fertilizer production and complete organic fertilizer production line configurations, where similar precision engineering principles apply.

From raw material processing to final packaging using automated fertilizer packing machine systems, every step embodies the essence of modern industrial engineering. The integration between different components – from granulators to packaging systems – creates seamless production flows that ensure consistent product quality and operational efficiency.

This technological evolution represents a paradigm shift in fertilizer manufacturing, where precision engineering and automated control systems have transformed production into a sophisticated industrial science that maximizes both efficiency and product quality.

Outstanding Production Characteristics: Redefining Fertilizer Manufacturing Standards

High Automation Level

Modern NPK fertilizer production lines employ advanced automated control systems, achieving unmanned operation throughout the entire process from raw material processing to finished product packaging. This intelligent production not only significantly enhances efficiency but also ensures consistency and stability in the manufacturing process.

Exceptional Production Efficiency

Through optimized design and the use of efficient equipment, production lines can rapidly and continuously produce large quantities of fertilizer. Sophisticated NPK fertilizer granulator machines and efficient fertilizer mixer machines work in harmony to create impressive production speeds.

Perfect Product Consistency

Utilizing precise batching systems and advanced granulation technology ensures that every fertilizer particle produced maintains high consistency in size, shape, and nutritional composition. Whether using disc granulators or double roller granulator machines, precise particle control is achievable.

Flexible Formula Adjustment

Production lines can flexibly adjust raw material ratios according to demand, producing NPK fertilizers with different formulations. This flexibility enables manufacturers to precisely meet the specific needs of different crops and soils.

Environmental Protection and Energy Conservation

Modern production line designs focus on energy conservation and emission reduction, significantly reducing energy consumption and environmental pollution through optimized processes and energy-saving equipment. From specialized fertilizer packing machine factories to entire production systems, environmental concepts are integrated throughout.

Core Equipment Systems: The Foundation of Precision Manufacturing

The exceptional performance of the NPK fertilizer manufacturing process relies on sophisticated equipment support. From raw material processing to finished product packaging, every stage features precise coordination of specialized equipment:

Fertilizer Mixer Machine

Ensures uniform raw material mixing

Disc Granulator

Achieves precise particle formation

Double Roller Granulator

Provides efficient granulation solutions

Automatic Packing System

Ensures perfect finished product packaging

Future-Oriented Fertilizer Manufacturing

With continuous advancements in agricultural technology, NPK fertilizer production processes will continue to develop towards greater intelligence, precision, and environmental sustainability. From optimization of NPK manufacturing processes to continuous equipment innovation, every improvement contributes to global food security. Future fertilizer production lines will place greater emphasis on resource utilization efficiency, minimizing environmental impact while ensuring product quality.

Core Technology System: NPK Manufacturing Process · NPK Fertilizer Manufacturing Process · NPK Fertilizer Granulator Machine · Fertilizer Mixer Machine · Fertilizer Packing Machine Factory · Disc Granulator · Double Roller Granulator Machine