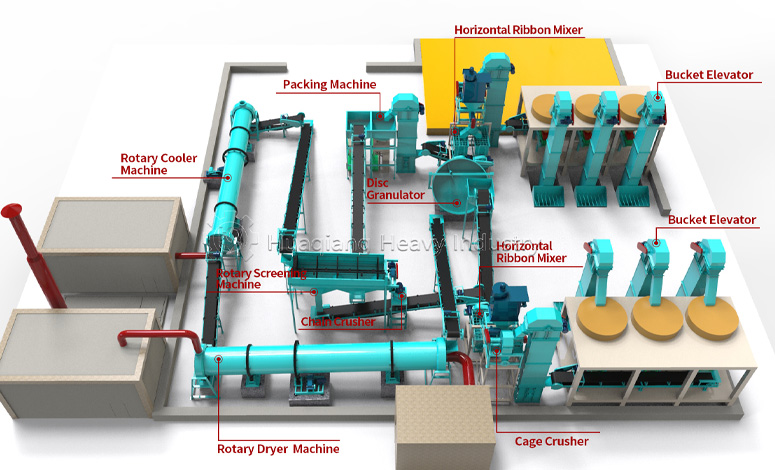

Step into a modern fertilizer production plant, and you’ll witness an intricate mechanical system operating with remarkable efficiency. This is the disc granulation production line—a precise process that transforms powdered fertilizer into uniform pellets. This system not only includes granulation equipment but also integrates crushing, mixing, drying, cooling, screening, and packaging stages, collectively forming a complete fertilizer production chain.

The heart of the disc granulator is a large, tilted, rotating disc. As raw powdered materials are fed in, they continuously roll and collide within the disc, gradually forming even small pellets—much like rolling a snowball. A spraying mechanism adds just the right amount of liquid at the perfect moment, aiding in the formation of these pellets. The beauty of this method lies in its imitation of natural pellet formation, only at a vastly accelerated pace.

Granulation is just the first step. Next, the pellets pass through a drum fertilizer dryer to remove excess moisture, then through a cooler to stabilize their structure. The screening machine acts as a strict quality inspector, ensuring only pellets of the correct size proceed further. Those too large or too small are sent to a crusher for reprocessing, minimizing waste to the greatest extent.

These seemingly simple pellets play a crucial role in modern agriculture. Compared to powdered fertilizers, pelletized fertilizers are easier to store and transport, less prone to caking, and more environmentally friendly during application. They release nutrients more gradually, reducing losses from wind and rain and minimizing water pollution.

From standalone disc granulation to complete production lines, advancements in fertilizer technology reflect the crystallization of human ingenuity. These small pellets carry the vital mission of nourishing crops and ensuring food security, quietly supporting the sustainable development of global agriculture.