In industries such as fertilizer, metallurgy, and chemicals, we often see uniform, regular spherical granules. These granules are not naturally formed; they are manufactured by intelligent equipment called a “Disc Granulation Production Line,” which “rolls” fine powder into shape like a snowball. This production line is a key link in the efficient utilization of powder materials and environmentally friendly production in modern industry and agriculture.

Core Principle: Ingenious “Snowballing”

The core principle of disc granulation is very intuitive, resembling an efficient “snowballing” process. Its central piece of equipment is a large, tilted, rotating disc. During production, the mixed raw powder materials (e.g., fertilizer powder, mineral powder) are continuously fed into the disc.

Because the disc is tilted and rotating, the material, under the combined action of gravity, centrifugal force, and friction, undergoes a complex motion: it rolls along the bottom of the disc while simultaneously climbing up the wall, only to roll back down upon reaching a certain height due to gravity. During this process, a specialized spraying device evenly sprays an appropriate amount of liquid (usually water or a binder) into the tumbling powder.

With the liquid acting as a “bridge,” the fine powder particles first agglomerate into tiny nuclei. These nuclei, during subsequent continuous tumbling, adhere to more powder layers like snowballs, layer by layer, being wrapped, compressed, and compacted. Their volume gradually increases, eventually forming uniform, dense spherical granules. The tilt angle and rotational speed of the disc are crucial for controlling granule size: a steeper angle and faster speed result in faster rolling and smaller granules, and vice versa.

The “All-Star” Cast of the Production Line

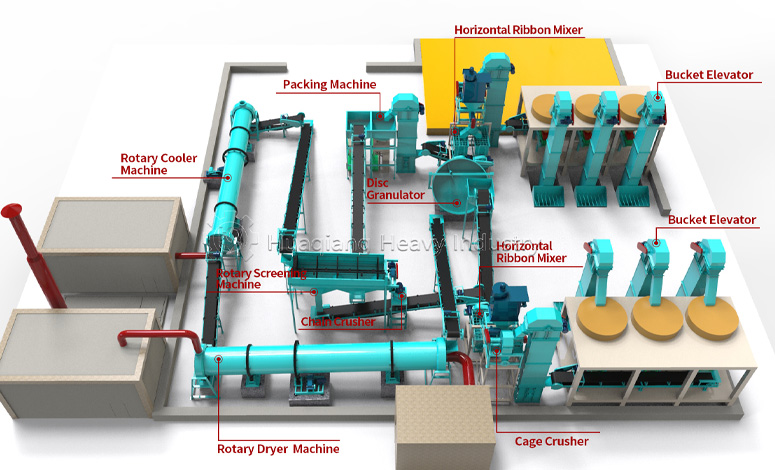

A complete disc granulation production line is far more than just a granulation disc; it is a coordinated system:

Raw Material Pre-treatment System: Responsible for crushing, screening, and precisely proportioning various raw materials to ensure uniform composition.

Mixer: Blends the proportioned powders uniformly, laying the foundation for granulation.

The Core – Disc Granulator: Executes the aforementioned “snowballing” task, transforming powder into “green” (moist) pellets.

Dryer and Cooler: The freshly produced “green pellets” lack sufficient strength and contain high moisture. A dryer is needed to remove moisture, followed by a cooler to lower the temperature and set the shape, giving them their final strength.

Screening System: The cooled granules have slight size variations. A vibrating sieve separates the finished product granules. Oversized granules are crushed and returned for re-granulation, while undersized powder is sent back to the fertilizer granulator disc to be used as “seeds,” achieving “zero waste” of raw materials.

Packaging System: Automatically weighs and packages the qualified finished granules.

Advantages and Applications

The disc granulation production line is widely used due to its prominent advantages: high pelletization rate, good granule strength, relatively low energy consumption, and simple operation and maintenance. It not only produces round and aesthetically pleasing granules but, more importantly, improves the physical properties of the material, making it less dusty, easier to transport and store, and allowing for controlled release of nutrients (as in fertilizers).

Today, from the compound fertilizers and urea applied in our fields, to the metal ore pellets used in metallurgical plants, and even to the pellet feed for poultry farming, there is likely a disc granulation production line working silently behind the scenes. It transforms seemingly useless dust into efficient products that support industrial and agricultural production, truly deserving to be called an industrial magician that turns waste into treasure.