In the world of modern agriculture, where soil conditions and crop needs can vary dramatically from field to field, the ability to produce customized nutrient formulas quickly and accurately is paramount. The npk blending fertilizer production line (also known as Bulk Blending, or BB Fertilizer) is the embodiment of this principle. It is a masterful system of precision and flexibility, designed to weigh, blend, and deliver tailored nutrient ratios with remarkable speed and accuracy.

Unlike complex chemical plants producing compound fertilizers, a blending line is a physical mixing operation. Its genius lies in its straightforward, modular design that delivers exactly what the farmer needs: the right N-P-K ratio, on demand.

The Core Philosophy: Precision, Flexibility, Speed

The value proposition of a BB fertilizer line rests on three pillars:

Formula Precision: The heart of the system is a computerized Batching & Weighing System that can measure each raw material component (e.g., granular urea, DAP, MOP, SSP, micronutrients) with extreme accuracy, ensuring the final blend perfectly matches the agronomist’s prescription.

Operational Flexibility: By simply changing the recipe in the control software, the same line can produce dozens of different formulations in a single day, seamlessly switching from a 20-10-10 corn blend to a 10-20-20 potato blend.

Economic Efficiency: With relatively low capital investment, minimal energy consumption (no drying or chemical processes), and high throughput, it offers one of the most cost-effective ways to produce a wide range of fertilizer products.

A Walk Through the Production Process

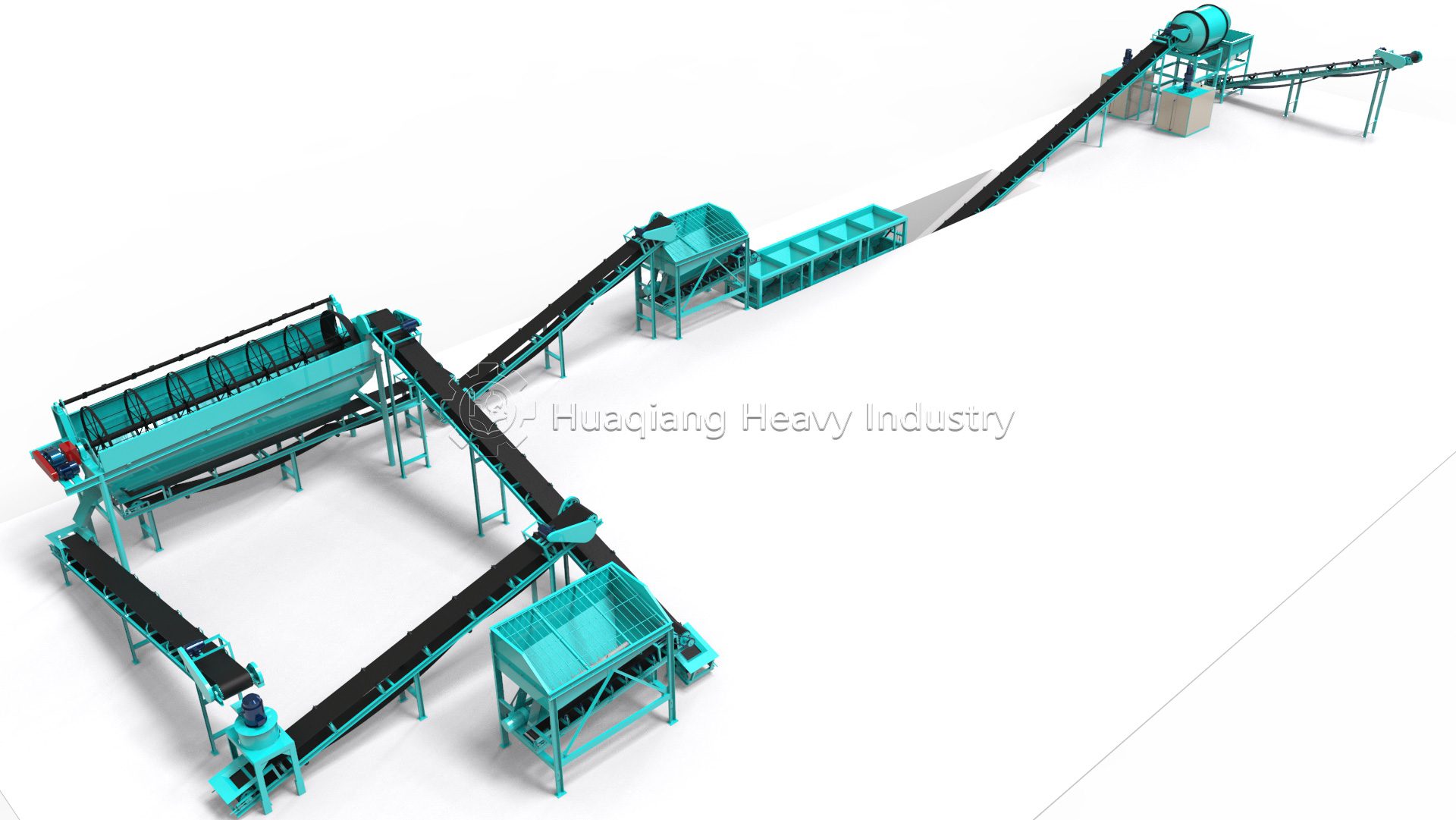

The process is a model of logical, linear flow:

Step 1: Material Reception & Storage

Granular raw materials (prilled urea, granular DAP, coarse MOP, etc.) are received and unloaded into loader feeding hoppers. They are then elevated and conveyed into dedicated storage bins or silos, one for each base component. Proper storage is critical to prevent caking and maintain material flowability.

Step 2: Precision Batching – The Digital Brain

This is the most critical stage. Upon a production order, the central control system (PLC) commands automatic discharge gates beneath each storage bin. Each component is weighed sequentially or simultaneously to the exact kilogram as per the digital recipe.

Step 3: Homogeneous Blending – The Heart of Uniformity

Once all ingredients are weighed, they are discharged simultaneously into the blending unit. A double axis mixer is often the preferred choice for its rapid, thorough, and gentle mixing action, achieving a highly homogeneous blend in 3-5 minutes without damaging the granules.

Step 4: Packaging & Dispatch

The finished blend is discharged into a holding hopper, from which it feeds directly into a high-speed automatic weighing and bagging machine for 25kg or 50kg bags. Alternatively, for large-scale farm clients, the blend can be sent directly to a bulk load-out station for truck loading, or into a big bag (FIBC) filler.

System Advantages at a Glance

| Feature | Advantage |

| Formula Agility | Produce dozens of custom blends from the same set of raw materials. |

| Low Capital & OpEx | No chemical reactors, dryers, or granulators mean lower cost. |

| Preservation of Quality | Gentle blending maintains the physical integrity (size, hardness) of the raw granules. |

| Rapid Changeover | Switch formulas in minutes with just a software command. |

| Minimal Cross-Contamination | Designed with clean-out points and sequencing to prevent residue carryover between batches. |

| Scalability | Lines can be designed from small (5 TPH) to very large (50+ TPH) capacities. |

The Smart, Connected BB Line

The modern blending line is an integrated node in a smart factory:

Full Automation & Traceability: From order entry to bag labeling, the process is automated. Each batch record—including raw material lot numbers, weights, and blend time—is stored digitally.

Advanced Quality Assurance: In-line metal detectors and optional automated samples ensure product purity and consistency.

Dust Control & Safety: Enclosed conveyors, dedicated dust collection systems at transfer points, and proper ventilation ensure a clean and safe working environment.

Conclusion

The NPK Blending Fertilizer Production Line is the ultimate solution for responsive, market-driven fertilizer production. It transforms the traditional “one-size-fits-all” approach into a precision nutrition service. By marrying robust mechanical handling with digital control, it delivers exactly what precision agriculture demands: the right nutrient, in the right place, at the right time, and in the exact proportion. For fertilizer distributors and cooperatives looking to add value and serve their farmers’ specific needs, a well-designed blending line is not just an investment in equipment—it’s an investment in flexibility, service, and growth.