For small and medium-sized fertilizer plants or companies transitioning into fertilizer production, setting up a complete chemical synthesis-based high-tower or rotary drum NPK compound fertilizer production line often faces significant hurdles in terms of huge investment, complex technology, and strict environmental approval. However, the market demand for compound fertilizers is clearly present. In this case, designing an NPK blended fertilizer production line based on physical blending technology becomes a wise choice due to its low investment, quick return, and high flexibility. It allows you to quickly produce customized fertilizers that meet the needs of specific crops at a reasonable cost. The following will break down the key design points of this production line.

Step One: Understanding the Core – What is “Blended Fertilizer”?

Unlike compound fertilizers granulated through chemical reactions, NPK blended fertilizer (also known as BB fertilizer) is produced by physically mixing single or binary basic fertilizers containing nitrogen, phosphorus, and potassium with matching particle sizes, according to a set ratio. Its greatest advantages are:

Flexible formulation: Nutrient ratios can be quickly adjusted according to different crops and soils.

Low investment threshold: No need for expensive granulation, drying, dust removal, and other large-scale equipment.

Nutrient preservation: No high-temperature chemical reactions, so the nutrient form remains unchanged.

The key to successful design is ensuring the accuracy of the formula and the uniformity of mixing, preventing product segregation during transportation and application.

Step Two: Core Equipment Selection – Precise, Efficient, and Durable

A standard small-scale blended fertilizer production line mainly consists of three core systems:

- Batching System: The Cornerstone of Precision

This is the first step in determining whether the product’s nutrient content meets the standards. For small factories, a multi-bin manual/semi-automatic batching system is recommended.

Core equipment: Set up 3-5 raw material bins (corresponding to basic raw materials such as urea, monoammonium phosphate, and potassium chloride), with a high-precision screw feeder or vibratory feeder under each bin.

Key control: Connect to an electronic weighing scale. The best solution is to use cumulative weighing: weigh all raw materials sequentially in the same weighing hopper to ensure absolute accuracy of the formula ratio. Although slower than multi-scale simultaneous weighing, it is more accurate and less costly, making it ideal for small-batch, multi-formula production. Measurement errors should be strictly controlled within ±0.5%.

- Mixing System: Ensuring Uniformity

Mixing is the core process that gives the product consistency. A twin-shaft paddle mixer is recommended.

Performance advantages: Its two counter-rotating shafts are equipped with multi-angle paddles, enabling efficient convective, shearing, and diffusive mixing of materials in both radial and axial directions, ensuring extremely high mixing uniformity (coefficient of variation CV ≤ 5%) within 60-120 seconds, with fast discharge and no residue.

Selection points: Choose the appropriate batch capacity (e.g., 1-2 tons/batch) based on your expected hourly output (e.g., 2-5 tons/hour). The material should be carbon steel with anti-corrosion treatment, and key parts should be wear-resistant.

- Packaging and Auxiliary Systems: Completing the Final Loop

Packaging machine: Choose an automatic quantitative packaging scale. The bag sewing method can be manual or automatic depending on the investment. This is crucial for improving efficiency and ensuring the appearance of the product.

Lifting and conveying: Use bucket elevators and belt conveyors to connect each section. The design should minimize material drop and transfer points to reduce dust and particle breakage.

Simple dust removal: Install a dust hood above the batching and feeding ports, connected to a small pulse bag dust collector. This is a necessary investment to meet environmental requirements and protect workers’ health.

Step Three: Site Planning and Cost Control – Practical Implementation

Site planning principles: The production line layout should follow a “straight-line” or “L-shaped” flow, compact and smooth. The core requirement is that the factory building height can accommodate the vertical installation space of the elevator and mixer, and leave passages for equipment maintenance and forklift operation. A typical small production line with a capacity of 2-5 tons/hour requires a production workshop area of approximately 200-400 square meters.

Core of cost control:

Equipment investment focus: Allocate the main budget to the batching and mixing systems, the two core links that determine quality, ensuring precision and uniformity. For conveying, packaging, and other auxiliary equipment, choose cost-effective domestic brands that meet basic functions.

Dynamic management of raw material costs: The profit of blended fertilizers is closely related to the price difference of raw material procurement. Establishing long-term partnerships with reliable raw material suppliers and learning to flexibly adjust main formulas based on fluctuations in bulk raw material prices are key to cost control.

Producing based on demand to reduce inventory: Fully utilizing the flexibility of “small batches, multiple formulas,” production is based on orders, avoiding the accumulation of large amounts of finished products and raw materials. A formula database management system (even a simple Excel spreadsheet) is crucial for efficient production scheduling.

Small scale, great potential

The essence of designing an NPK blended fertilizer production line for small factories lies in “precision, flexibility, and practicality.” It doesn’t need to pursue full automation, but it must be precise and reliable in the mixing and blending stages that determine product quality; it doesn’t require massive production capacity, but it must have the ability to quickly respond to the market and adjust formulas. Such a production line is not only a quick way to enter the fertilizer market, but also a powerful tool for serving local agriculture and providing customized nutritional solutions. Through careful design and sound operation, small factories can completely establish a unique and stable competitive advantage in the regional market.

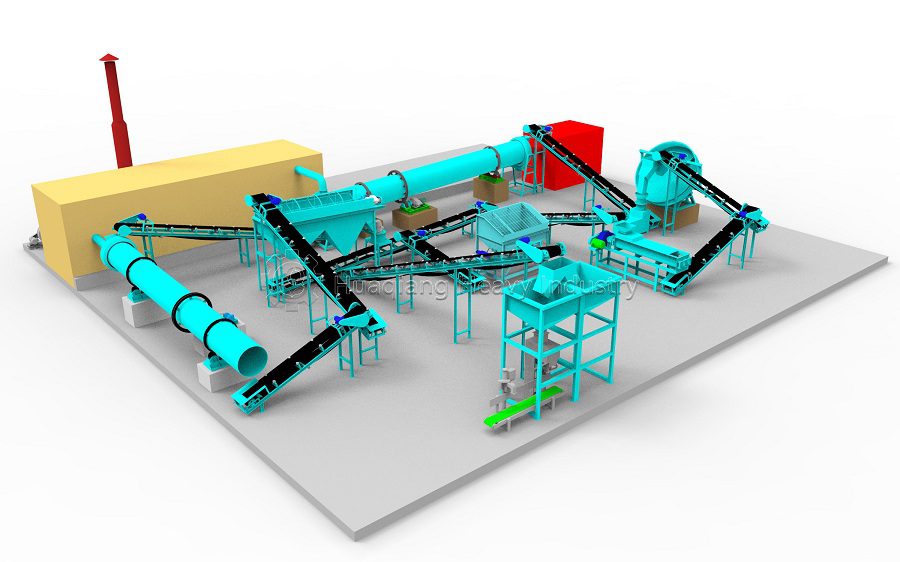

While a basic blending line serves as an excellent entry point, a growing business may need to expand its product range to include granulated fertilizers. This upgrade involves investing in professional fertilizer manufacturing equipment beyond a basic npk bulk blending machine. For producers aiming to create dust-free, dense granules without chemical reactions, a roller press granulator production line is an ideal step up. This line centers on a double roller press granulator, which compresses blended powder into flakes or irregular granules through mechanical force, offering an energy-efficient granulation path. For facilities focused on the premium organic market, integrating High-end organic fertilizer equipment—such as advanced compost turners and specialized granulators—alongside or separate from the NPK line, creates a versatile manufacturing setup capable of producing both blended and granulated products to meet diverse market demands.