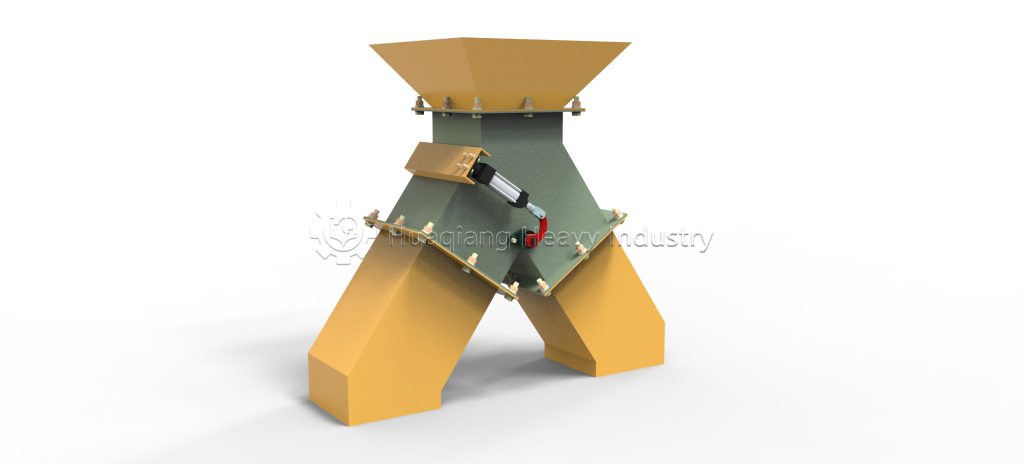

What is a Pneumatic Three-way Valve?

The Pneumatic Three-way Valve is a crucial control component in fertilizer production lines used for material diversion. Driven by compressed air, it can quickly switch material flow direction, distributing a single input channel to one of two different output channels, or merging two input channels into one output channel [1].

Pneumatic three-way valves play a crucial role in fertilizer production lines by enabling precise flow control and diversion of raw materials and intermediate products. These valves facilitate efficient routing of liquids, gases, and slurries between different process stages like mixing, reaction, granulation, and drying. Their rapid switching capability ensures continuous operation while preventing cross-contamination between different fertilizer formulations. By automating material flow management, they enhance process reliability, improve production efficiency, and allow quick adaptation to varying production requirements. The valves’ durability in handling corrosive chemicals makes them particularly valuable in the demanding environment of fertilizer manufacturing.

Role in Fertilizer Production Lines

In modern fertilizer production, pneumatic three-way valves primarily serve the following important functions:

- Material Flow Control: Distributing raw materials or semi-finished products to different processing stages according to production needs. For example, directing mixed fertilizer granules to different drying lines.

- Production Line Switching: When one production line requires maintenance, materials can be quickly switched to a backup line to ensure continuous production.

- Quality Grading: Diverting finished fertilizer products of different quality grades to different packaging lines for product classification management.

- System Protection: When abnormalities are detected, materials can be quickly diverted to safety channels to prevent equipment damage [2].

Relationship with Other Equipment

Pneumatic three-way valves typically work in coordination with the following equipment:

- PLC Control Systems: Receiving control signals and providing status feedback

- Air Supply Units: Providing clean, dry compressed air

- Conveying Systems: Such as belt conveyors, screw conveyors, etc.

- Sensors: Including position sensors, material detection sensors, etc.

Considerations for Selecting Pneumatic Three-way Valves

When selecting appropriate pneumatic three-way valves for fertilizer production lines, consider:

- Material characteristics (particle size, moisture, corrosiveness)

- Working pressure and ambient temperature

- Switching frequency requirements

- Sealing performance requirements

- Compatibility with existing control systems