In the field of organic fertilizer production, the disc granulation production line is attracting increasing attention from small and medium-sized enterprises (SMEs) with its unique advantages. What exactly makes this technology so appealing? Let’s explore.

Streamlined and Efficient Process

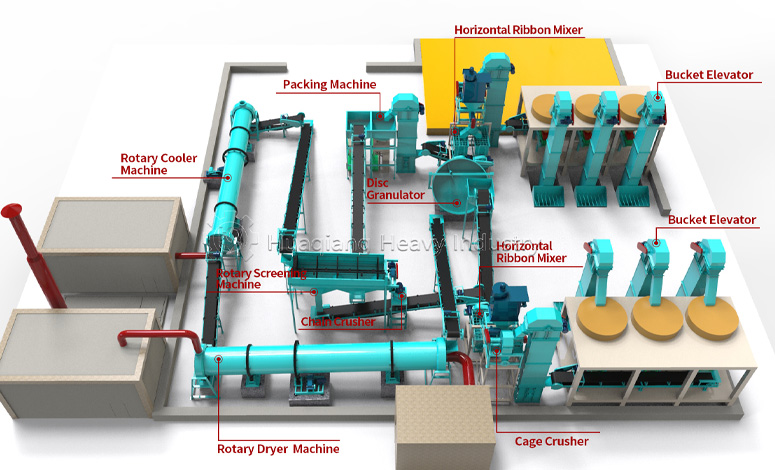

Compared to traditional fertilizer production lines, disc granulation technology demonstrates surprising simplicity. The production process is shortened by nearly 30%, with straightforward equipment structure that even novice operators can quickly master. This “less is more” design philosophy not only reduces maintenance costs but significantly improves production efficiency.

“Fast return on investment” is the most frequently heard praise for disc granulation lines. With initial investment at only 60%-70% of traditional equipment yet achieving over 85% production capacity, this cost-performance ratio gives hope to capital-constrained SMEs.

Remarkable Material Adaptability

Remarkably, this production line has an “astonishing appetite.” From common nitrogen sources like urea, ammonium chloride to ammonium sulfate, and even various organic waste materials, it can “digest” and transform them into uniform granules. This extensive material adaptability provides enterprises with tremendous formulation flexibility to adjust product composition according to market demands.

The Ideal Partner for Growing Businesses

For emerging organic fertilizer companies, the disc granulation line acts like a considerate business partner. It doesn’t demand massive factory space, complex supporting equipment, nor does it create heavy financial burdens. These “small but beautiful” characteristics perfectly match SMEs’ need for “traveling light” in business development.

With the flourishing development of organic agriculture, disc granulation technology is opening a gateway to success for small and medium-sized fertilizer enterprises with its unique charm. Could this be the wisest production choice available today?