In the vast landscape of fertilizer granulation, if modern rotary drum granulation represents the paradigm of efficient, continuous industry, then the Disc Granulation Production Line is more akin to a precise, visual craft. With its unique working principle, unparalleled flexibility, and classic “balling” aesthetics, it consistently holds an irreplaceable position globally, especially in small to medium-scale fertilizer production, specialty fertilizer development, and pilot plant applications.

Core Advantages: The Perfect Balance of Visibility, Flexibility, and Economy

The heart of a disc granulator (or pan granulator) is a large, inclined, rotating disc. Its strengths stem precisely from this simple yet ingenious design:

Unmatched Process Visibility & Control: This is its most salient advantage. Operators can directly observe the entire process inside the pan: material movement, wetting, nucleation, and growth-by-layering. The increase in pellet size is as clear as watching a snowball roll, allowing for immediate fine-tuning of the tilt angle, rotation speed, and liquid spray rate based on real-time conditions, achieving “what-you-see-is-what-you-get” precision control.

Excellent Particle Uniformity & Sphericity: Inside the inclined disc, materials undergo a regular spiral rolling motion due to the combined effects of gravity, centrifugal force, and friction. This motion naturally creates a classification effect. Particles that meet the size criteria automatically discharge over the rim, while smaller ones remain inside to continue “growing,” thereby inherently ensuring uniform discharge and near-perfect roundness of the pellets.

High Flexibility & Adaptability: A single machine can easily produce products of different size specifications (typically 2-8mm) with simple adjustments. It has wide adaptability to raw materials and is particularly suitable for formulations requiring binders or precise liquid-to-solid ratios. It is widely used for granulation in organic fertilizer, compound fertilizer, feed, metallurgical powders, and other fields.

Economic Investment & Operation: Relatively simple in structure and compact in footprint, its initial investment and maintenance costs are typically lower than large-scale rotary drum or twin-shaft granulation systems. With lower energy consumption, it offers excellent cost-effectiveness for non-24/7 continuous operation or small-batch, multi-product production models.

Production Line Process: A Streamlined and Efficient Pathway

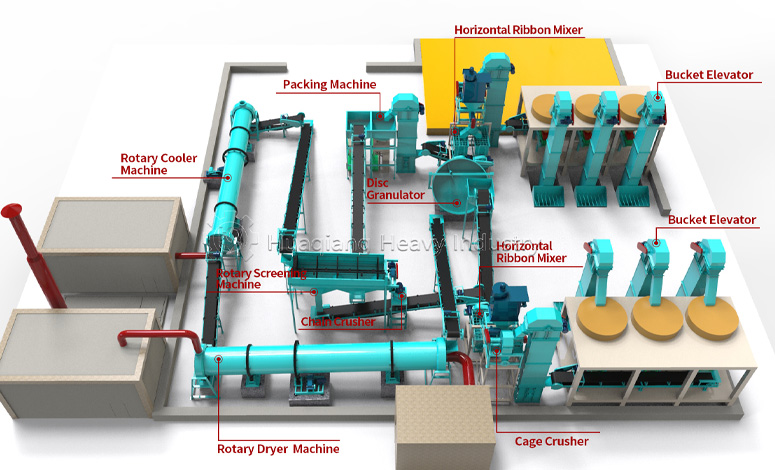

A typical disc granulation production line is a marriage of efficiency and simplicity:

Raw Material Pre-treatment: Raw materials (if needed) are first crushed and then uniformly pre-mixed by a Double Shaft Mixer or other blending equipment. This is the critical first step to ensure homogeneous composition for granulation.

Core Granulation: The blended material is quantitatively fed to the top of the Disc Granulator. Inside the rotating pan, liquid (water, binder, or melt) is precisely added via a spray system. The fine powder gradually agglomerates into pellets through rolling. The operator, like a gardener, meticulously oversees the entire process from “seed” to “fruit.”

Drying & Cooling: The wet pellets are conveyed into a drum fertilizer dryer to remove excess moisture and achieve required strength. They then enter a Cooler to reduce temperature for subsequent screening and storage, preventing caking.

Screening & Packaging: The cooled pellets are graded by a Vibrating Screen. On-spec product goes to the finished product silo. Oversized pellets are crushed and recycled. This creates a near-zero-waste material loop.

Exhaust Gas Treatment: Dust-laden exhaust gases from the drying and cooling processes are treated by a Dust Removal System (e.g., cyclone, bag filter, or scrubber) before emission, meeting environmental standards.

Application Scenarios: The Classic, Irreplaceable Choice

The disc granulation line is the ideal choice for:

Small to Medium-Scale Fertilizer Producers: Seeking quick ROI and production flexibility.

Specialty Fertilizers & Pilot Plants: Requiring frequent formula adjustments and small-batch trials.

Markets Valuing Product Appearance: Where high pellet roundness and uniformity are critical.

Organic & Bio-Fertilizer Production: Where raw materials are more adhesive and require intuitive process control.

Conclusion

The disc granulation line transforms a complex physico-chemical process into an intuitive visual spectacle. It may not be the largest in scale, but it is one of the most “artisanal” and easily mastered granulation methods. In an era that values customization, precision, and cost-effectiveness, it proves itself, with its classic charm and reliable performance, to remain a bright and highly practical star in the field of fertilizer and powder granulation.