Core Advantages of Disc Granulation Production Line

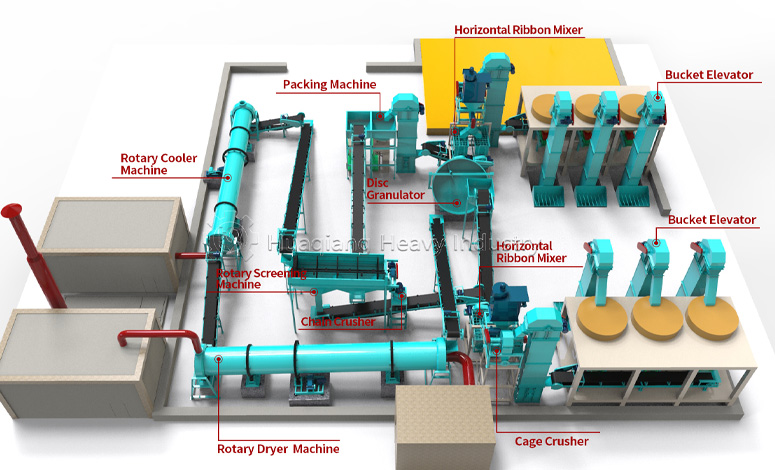

The Organic Fertilizer Disc Granulation Production Lineholds a prominent position in organic fertilizer manufacturing equipment due to its unique granulation method. Its most notable advantage is the gentle granulation process, particularly suitable for organic materials containing live microorganisms. With adjustable inclination (45-60°) and rotational speed (30-50rpm), it can handle various organic materials from powdery to viscous while preserving microbial activity.

Standard disc granulation lines typically process 1-10 tons/hour with granulation rates reaching 85-92%, producing more spherical granules than other methods.

Key Efficiency Improvement Measures

Enhancing production line efficiency requires focus on: raw material pretreatment (25-35% moisture content), dynamic adjustment of disc speed/angle, regular cleaning (every 8 hours), and automated control systems. Adding 5-10% binders (like bentonite) significantly improves pelletization, while variable frequency drives adapt to different materials.

Unique Characteristics of the Production Line

Disc granulator produces organic fertilizer with uniform particle size (2-5mm), smooth surfaces, and moderate strength (10-20N/granule). This open granulation method allows real-time process observation and adjustment, with 30-40% lower energy consumption than extrusion granulation. Crucially, it perfectly preserves active components in organic matter – essential for premium bio-organic fertilizers.

With organic agriculture’s rapid growth, disc granulation technology is evolving toward intelligent systems. Integrated sensors and AI controls now automatically adjust parameters for varying materials, elevating the efficiency of converting organic waste into high-value fertilizers to unprecedented levels.