In the field of fertilizer production, disc granulators have become the preferred equipment for many manufacturers due to their unique advantages. But what types of fertilizer production are most suitable for disc granulators? What tangible benefits can they bring? This article will answer these questions one by one.

1. Application Scope: Which Fertilizer Productions Suit disc Granulators?

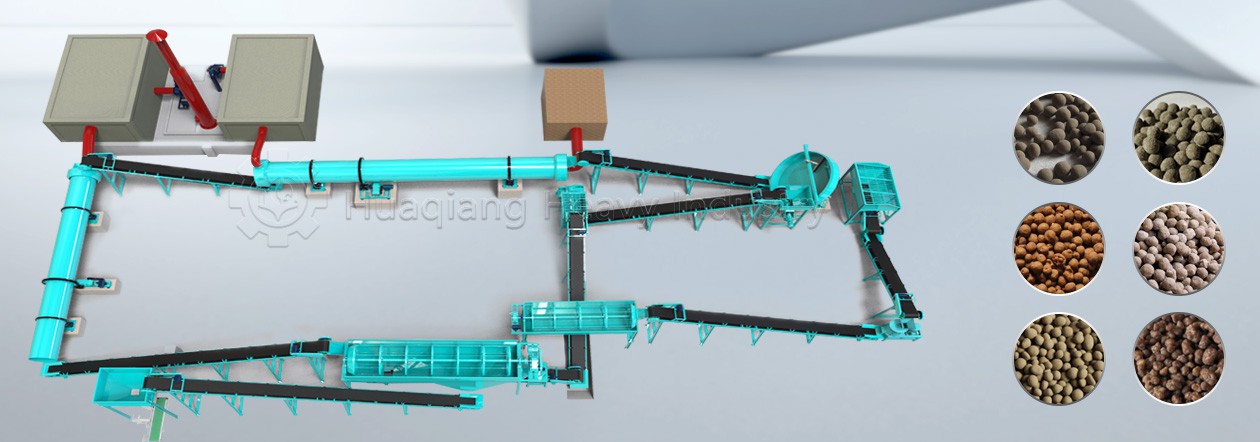

The disc granulator production line, featuring a rotating inclined pan for agglomerating materials, differs from traditional fertilizer production lines primarily in its granulation mechanism. While traditional lines often use extrusion or compaction methods, disc granulators employ a gentle tumbling action that creates more spherical, uniform pellets with lower energy consumption. This method is particularly effective for organic fertilizers, allowing better control over particle size distribution and producing less dust compared to conventional granulation systems.

disc granulator production lines are particularly suitable for the following types of fertilizer production:

- Organic-Inorganic Compound Fertilizers: Effectively handles the granulation of mixtures containing both organic and inorganic materials

- Bio-Organic Fertilizers: Can granulate temperature-sensitive biological agents under mild conditions

- NPK Compound Fertilizers: Especially meets the needs of small and medium-sized compound fertilizer producers

- Micronutrient Fertilizers: Allows precise control of micronutrient addition ratios

- Special Formula Fertilizers: Easy to adjust formulas for customized production needs

Disc Granulator

2. Core Advantages: Why Choose disc Granulators?

| Advantage | Specific Performance | Value Proposition |

| High Flexibility | Quick formula changes and process parameter adjustments | Meets multi-variety, small-batch production needs |

| Low Energy Consumption | 30-50% more energy efficient than other granulation methods | Significantly reduces production costs |

| High Granulation Rate | Typically reaches 85-95% | Reduces material waste, improves economic benefits |

| Easy Operation | High automation level with minimal manual intervention | Reduces labor costs, improves production efficiency |

| Strong Adaptability | Can process various material combinations | Exdiscds product line, enhances market competitiveness |

Disc Granulation Production Line

3. Practical Value: Economic Benefits of disc Granulators

According to actual production case studies, disc granulator production lines can bring the following economic benefits:

- Quick ROI: Typically recovers equipment investment within 1-2 years

- Low Production Costs: 15-30% lower comprehensive production costs than traditional granulation methods

- Stable Product Quality: Uniform particle size with moderate strength, highly accepted by the market

- Significant Environmental Benefits: Lower energy consumption and reduced emissions