In the world of agricultural productivity, fertilizer production lines are the unsung heroes feeding our crops and soils. But what exactly distinguishes organic fertilizer production from NPK manufacturing? Let’s break down these essential processes that power modern agriculture.

The Production Line Spectrum

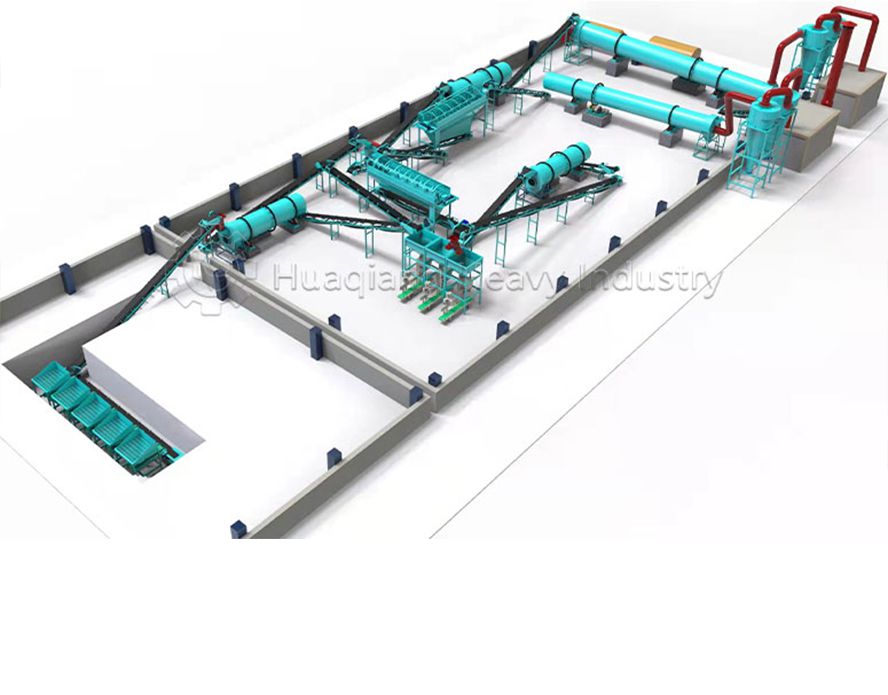

At their core, all fertilizer production lines share common goals: transforming raw materials into nutrient-rich plant food. However, the approaches differ dramatically between organic and chemical (NPK) fertilizers:

| Feature | Organic Fertilizer Production | NPK Fertilizer Production |

| Raw Materials | Animal manure, plant residues, food waste | Chemical compounds (ammonia, phosphates, potash) |

| Key Process | Biological decomposition (composting) | Chemical synthesis |

| Nutrient Control | Variable, nature-dependent | Precise N-P-K ratios |

| Production Time | Weeks to months | Hours to days |

The Organic Journey

The organic fertilizer production process is essentially nature’s recycling system industrialized. It begins with collection of organic wastes which undergo:

- Pre-treatment:Sorting and initial crushing

- Composting:Microbial breakdown over 4-8 weeks

- Refinement:Crushing, screening, and granulation

- Curing:Final stabilization

The NPK Manufacturing Process

NPK fertilizer production is a marvel of chemical engineering precision. The process typically involves:

- Raw material preparation:Precise weighing of chemical components

- Chemical reaction:Often using the Haber-Bosch process for nitrogen

- Granulation:Creating uniform pellets for even distribution

- Coating:Adding anti-caking agents

Intersecting Technologies

Interestingly, modern production lines often blend technologies from both worlds. Many organic fertilizer plants now incorporate:

- NPK fortification to boost nutrient content

- Advanced granulation techniques from chemical production

- Precision control systems adapted from NPK manufacturing

As agriculture evolves to meet sustainability challenges, the lines between organic and chemical fertilizer production continue to blur, creating exciting opportunities for hybrid systems that combine the best of both approaches.