How to transform agricultural waste into black gold? This system has the perfect answer

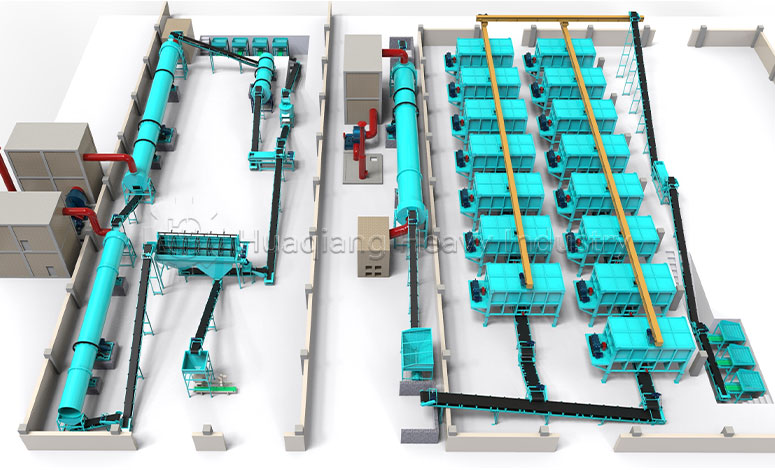

The bio organic fertilizer production process relies on specialized fertilizer machines as its backbone – from crushers that prepare raw materials to granulators that shape the final product. These machines work in harmony to transform organic waste into nutrient-rich fertilizer, with each piece of equipment playing a vital role in this sustainable alchemy.

While an organic fertilizer production line handles basic composting processes, a bio organic fertilizer production system goes further by incorporating microbial enhancement and precise quality control. The relationship is evolutionary – bio-organic production represents the advanced, scientifically-enhanced version of traditional organic fertilizer manufacturing, delivering superior results through refined technology.

The Magnificent Transformation

Imagine smelly livestock manure and mountains of crop straw—these troublesome agricultural wastes are first “chewed” by crushers’ “teeth,” then meet precisely measured fermentation agents. Like a magician’s preparation, the well-mixed materials enter fermentation areas, beginning their magical metamorphosis journey.

In fermentation tanks—these “microbial kitchens”—billions of probiotics showcase their skills. Feeding on organic waste at 60-70°C, they act like countless tiny chefs, “cooking” complex organics into plant-friendly nutrient feasts. Regular turning provides kitchen ventilation, ensuring every “chef” gets sufficient oxygen.

Precision Post-Processing

After drying, fermented materials enter granulators’ “plastic surgery rooms.” Here, loose materials are shaped into uniform pellets, like stringing scattered pearls into necklaces. Screening machines serve as strict quality inspectors, ensuring every fertilizer pellet meets standards. Finally, specific microbial agents and trace elements are added according to different crops’ needs, like customizing exclusive menus for various guests.

Final Quality Assurance

Automatic packagers fill finished products with astonishing precision—each bag’s weight error stays within 10 grams. Quality checks resemble airport security, strictly testing over 30 indicators including nutrient content and microbial activity. Only fully compliant products earn “boarding passes” to enter markets and contribute to green agriculture.

From avoided waste to sought-after bio-fertilizer, this production line achieves material recycling while showcasing modern agricultural technology’s magic. In today’s sustainability-focused world, it’s becoming a crucial bridge connecting environmental protection and agriculture, ensuring every organic resource reaches its full potential.