Introduction

The NPK fertilizers are inorganic compound fertilizers containing specific ratios of N, P, and K. Different NPK formulations are designed to meet the nutritional requirements of various crops. NPK fertilizers are manufactured through a series of chemical and physical processes to ensure balanced nutrient composition.This production line requires low equipment investment, delivers rapid results, and offers strong economic returns.

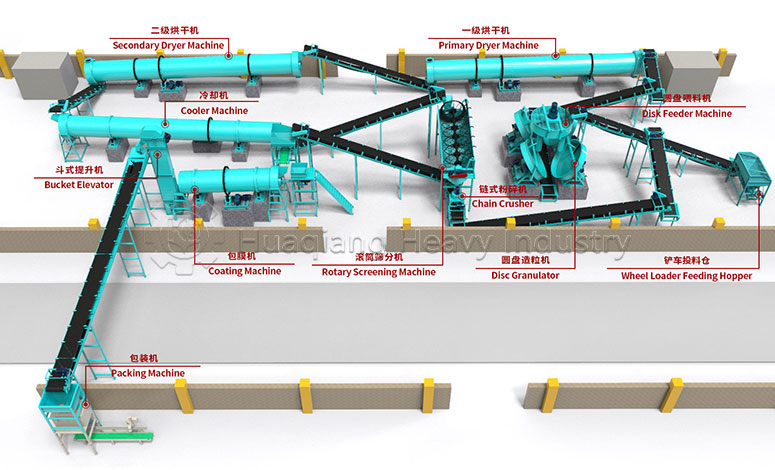

Composition of NPK Compound Fertilizer Production Line

A complete NPK compound fertilizer production line includes various equipment such as a fertilizer granulator, fertilizer crusher, fertilizer mixer machine, fertilizer screener machine, fertilizer dryer, fertilizer cooler and more.For this NPK fertilizer production line, let’s first examine the fertilizer granulator in detail. Fertilizer granulator machine is an import part in both organic and compound fertilizer production line. Because the fertilizer granulator can powder materials into fertilizer granules quickly. And the granulated fertilizer has features of easy transport,storage and long effect,which help you make more profits from fertilizer production business.

The fertilizer dryer machine removes excess moisture from fertilizer granules to ensure product quality and stability.The primary function of the fertilizer cooler machine is to rapidly reduce the temperature of dried hot fertilizer granules to an optimal level, ensuring the stability of subsequent coating processes.

The main function of the fertilizer coating machine in the compound fertilizer production line is to add a protective coating to the fertilizer particles usually to enhance the anti-caking and moisture-resistant properties of fertilizer granules, thereby improving storage stability. Moreover the surface of the coated fertilizer particles is smooth, the fluidity is better, and it is more suitable for packaging and storage.At the same time, it can effectively avoid agglomeration or water loss during transportation and use.

Advantages of NPK Compound Fertilizer Production Line

1、Low investment, high efficiency and remarkable economic benefits

Features advanced technology for energy savings and reduced consumption.

2、Environmentally friendly operation without wastewater, exhaust, or residue emissions.

3、Smooth operation with minimal maintenance requirements.

4、Ensures uniform, aesthetically pleasing fertilizer granules.

The material has wide adaptability and is suitable for granulation of all kinds of raw materials such as compound fertilizer, medicine, chemical industry, feed and so on, and the product has high granulation rate.

Features of NPK Fertilizer Production Line

The NPK compound fertilizer production line is engineered with our proprietary advanced technologies, ensuring reliable machine operation, premium product quality, and effortless maintenance.

Adaptable to diverse raw material formulations with exceptional production flexibility, delivering high pelletization rates, low comprehensive energy consumption, and zero pollution emissions.

The NPK fertilizers production line features optimized design with easily adjustable capacity control.