In the production of fertilizer, choosing the right dosing equipment is the key to ensure fertilizer quality and production efficiency. For fertilizer granulator, organic fertilizer production line and NPK fertilizer production line, how to choose the most suitable batching equipment according to fertilizer formula?

- Clear fertilizer formula requirements

In the production of fertilizer, choosing the right dosing equipment is the key to ensure fertilizer quality and production efficiency. For fertilizer granulator, organic fertilizer production line and NPK fertilizer production line, how to choose the most suitable batching equipment according to fertilizer formula?

- Clear fertilizer formula requirements

Before selecting the batching equipment, it is necessary to first clarify your fertilizer formula needs. Different fertilizer formulations have different requirements for ingredient accuracy, mixing uniformity and production efficiency. For example, a NPK fertilizer line may require high-precision batching equipment to ensure the correct ratio of nitrogen, phosphorus, and potassium; The organic fertilizer production line may pay more attention to the corrosion resistance and mixing capacity of the equipment.

- Consider device performance characteristics

According to the requirements of fertilizer formula, select the dosing equipment with corresponding performance characteristics. For example, for occasions where high-precision batching is required, batching equipment using electronic weighing technology can be selected; For organic fertilizer production lines that require a large amount of mixing, you can choose equipment with strong mixing capacity and anti-corrosion properties.

- Pay attention to device compatibility

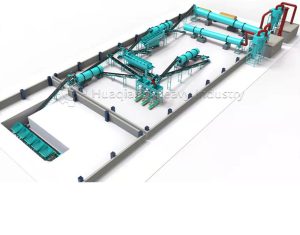

When selecting the batching equipment, it is also necessary to consider its compatibility with existing fertilizer granulators, organic fertilizer production lines or NPK fertilizer production lines. Ensure that equipment can be seamlessly integrated into existing production lines to avoid productivity loss or quality issues due to equipment incompatibilities.

- Consider ease of operation and maintenance cost

In addition to equipment performance and compatibility, it is also necessary to consider the ease of operation and maintenance costs of the equipment. Selecting the batching equipment with simple operation and easy maintenance can reduce labor costs and improve production efficiency. At the same time, low maintenance costs also mean lower operating costs.

To sum up, according to the fertilizer formula selection of suitable batching equipment needs to consider the formula requirements, equipment performance, compatibility, operation convenience and maintenance costs and other aspects. Through careful comparison and selection, you can find the most suitable batching equipment for your own production line, thus ensuring the quality and production efficiency of fertilizer products.