In the vast field of fertilizer production line, choosing the right organic fertilizer production method and equipment is as important as selecting the best nutrient source for crops. Faced with a wide range of fertilizer production equipment on the market, how to make a wise choice according to the characteristics of fertilizer has become the focus of attention of many manufacturers. This article will take “fertilizer granulator“, “organic fertilizer production line” and “NPK fertilizer production line” as keywords to reveal the mystery of this selection process for you.

We need to define the basic characteristics of fertilizer. Different fertilizers have different requirements for production equipment due to their differences in raw materials, ingredients and application scope. For example, organic fertilizer with its environmental protection, long-term characteristics, more and more favored by the market. In the production process of organic fertilizer, fermentation, granulation and other links are particularly critical.

For the fermentation process, it is important to choose a fermentation equipment that can fully mix raw materials and control temperature and humidity. This is not only related to the quality and efficiency of organic fertilizer, but also directly affects the smooth progress of subsequent processes. Our fermentation equipment uses advanced stirring and aeration technology to ensure that raw materials are fermented in the best condition, laying a solid foundation for the production of organic fertilizer.

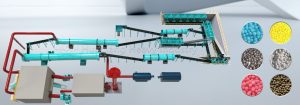

Next comes the granulation process. Fertilizer granulator as one of the core equipment of organic fertilizer production line, its choice can not be ignored. An excellent fertilizer granulator should be able to adapt to the characteristics of different fertilizer raw materials to achieve an efficient and stable granulation process. Our fertilizer granulator adopts a new drying technology, the closed granulation process effectively reduces the dust leakage, protects the working environment, and also meets the environmental requirements.

For the NPK fertilizer production line, the requirements for equipment are more stringent because it involves the precise matching and mixing of a variety of nutrients. Our NPK fertilizer line uses advanced dosing systems and mixing equipment to ensure an even distribution of nutrients to meet the needs of different crops.