In today’s pursuit of sustainable agriculture, organic fertilizer production has become a vital link between environmental protection and efficient farming. How does this magical production line transform waste into “black gold”? Let’s unveil its mysteries.

The Win-Win Approach of Environmental Protection and Energy Saving

The organic fertilizer production line is first and foremost an excellent “environmental doctor.” It can efficiently process various organic wastes, from livestock manure to crop straw, all of which can be “digested.” Compared to traditional landfill or incineration methods, this approach significantly reduces environmental pollution risks. More surprisingly, through continuously optimized processes and equipment configuration, the production line reduces its own energy consumption while “healing the environment,” achieving dual goals of environmental protection and energy conservation.

This production line is more like a master “alchemist,” skilled at turning “waste” into “treasure.”

The Perfect Closed Loop of Resource Recycling

Agricultural and livestock waste finds its best destination here, transforming into nutrient-rich organic fertilizer through scientific conversion processes. This resource recycling model not only solves waste disposal challenges but also provides sustainable nutrient sources for agricultural production, truly realizing the ecological cycle of “from the field, back to the field.”

The Art of Stable Quality Production

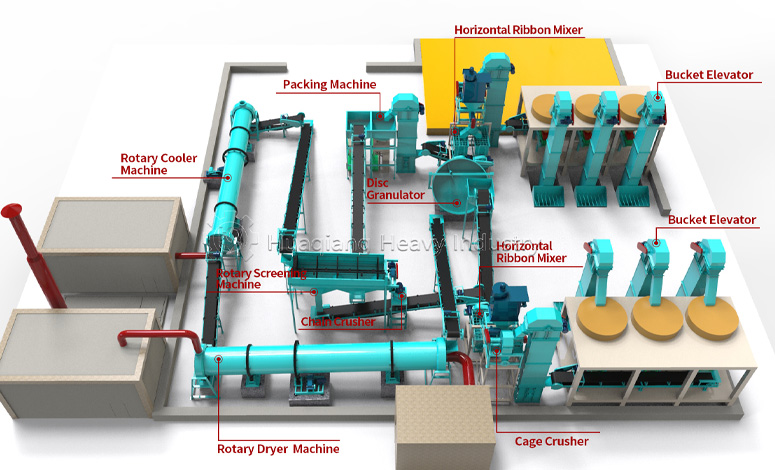

Precision control is the core skill of this fertilizer production line. From temperature and humidity regulation during fermentation to the fine mastery of granulation technology, every step is carefully designed. What ultimately reaches users is high-quality organic fertilizer with uniform nutrient content, consistent particle size, and appropriate moisture levels. This stability ensures reliable fertilizer performance, giving farmers peace of mind.

The Intelligent System with Flexible Adaptability

Faced with diverse raw materials and market demands, this production line demonstrates remarkable adaptability. It can adjust formulas and process parameters flexibly according to raw material characteristics and target market needs, producing different types of organic fertilizers with distinct features. This flexibility allows it to meet various usage demands, from large-scale farms to household gardening.

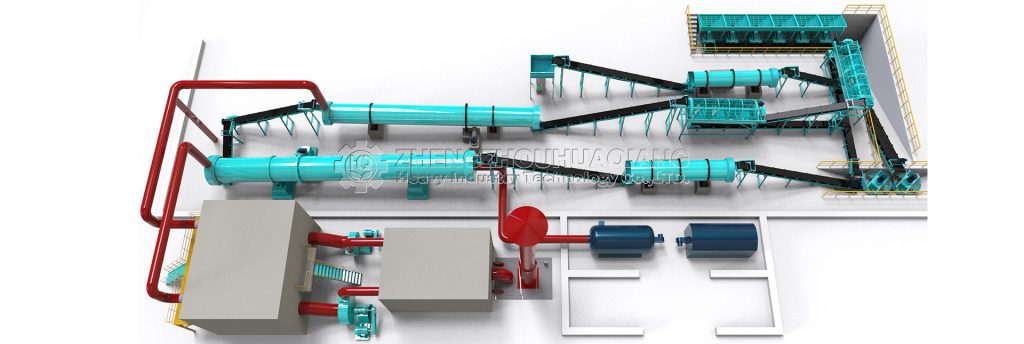

The Modern Factory Empowered by Automation

Entering a modern organic fertilizer production workshop, you’ll be amazed by its highly automated production scene. From raw material pretreatment to finished product packaging, the entire process requires almost no manual intervention. The intelligent control system acts like a tireless “conductor,” precisely coordinating every process step, improving production efficiency while minimizing human errors to ensure consistent product quality.

This magical organic fertilizer production line, in its unique way, demonstrates modern agriculture’s relentless pursuit of environmental protection and efficient resource utilization. It is not only a crystallization of technology but also a vivid embodiment of harmonious coexistence between humans and nature.