Organic fertilizers are typically derived from organic waste. Unlike chemical fertilizers, the long-term use of chemical fertilizers can have adverse effects on plants and soil. In contrast, organic fertilizers not only benefit plants and soil but also promote the recycling of organic waste, playing a significant role in environmental protection.

So, what does a complete organic fertilizer production line include?

The production process of organic fertilizers involves composting organic waste and the further processing of fermented organic waste.

The composting of organic waste itself is also a fermentation process. First, the organic waste is piled in a trough and turned using a compost turning machine to accelerate composting while preventing anaerobic fermentation. After the fermentation process is completed, the organic fertilizer undergoes further processing.

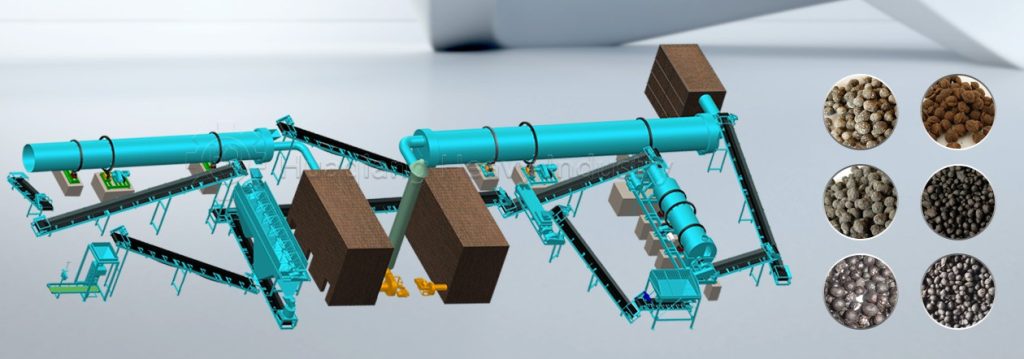

The entire further processing of organic fertilizer granulator primarily includes crushing, granulation, drying, cooling, screening, and packaging. The main machines used are fertilizer crusher, fertilizer granulator, fertilizer dryer, fertilizer cooler, fertilizer screening machine and fertilizer packaging machine.

Fertilizer crusher machine and fertilizer mixer machine: Because granule making has higher standard on organic fertilizer powder, you should guarantee homogeneous powder.

Fertilizer granulator: In this step, powdery organic fertilizer will be granulated into pellets.

Fertilizer dryers machine and Fertilizer coolers machine: These machines regulate the moisture content of fertilizer granules, extending their shelf life.

Fertilizer Screening Machine: It separates substandard granules from qualified fertilizer particles. Subsequently, the belt conveyor transports the unqualified organic fertilizer granules back to the crusher for re-granulation, while the qualified particles are sent to the packaging machine.

Fertilizer Packaging Machine: Packs fertilizer granules for convenient transportation and storage.