In the world of NPK fertilizer production line, five key pieces of equipment work together like a well-orchestrated symphony, perfectly blending nitrogen (N), phosphorus (P), and potassium (K) to create superior quality fertilizers.

Core Equipment Lineup

- Raw Material Crusher

The “Teeth” of the fertilizer Production Line

As the first critical stage, crushers break down materials like urea, ammonium phosphate, and potassium chloride into uniform particles. Cage crushers, with their counter-rotating dual-cage design, efficiently process hard materials, creating ideal conditions for subsequent mixing.

- Batching System

The “Brain” of the Line

Precision electronic batching systems act like meticulous chemists, using load cells and PLC controls to ensure accurate N-P-K ratios. Modern systems achieve ±0.5% accuracy, guaranteeing product consistency.

- Dual-Shaft Mixer

The “Magician’s Hand”

With counter-rotating shafts, this equipment achieves thorough mixing. Specially designed blades prevent clumping, ensuring each fertilizer particle contains balanced nutrients, with mixing uniformity exceeding 95%.

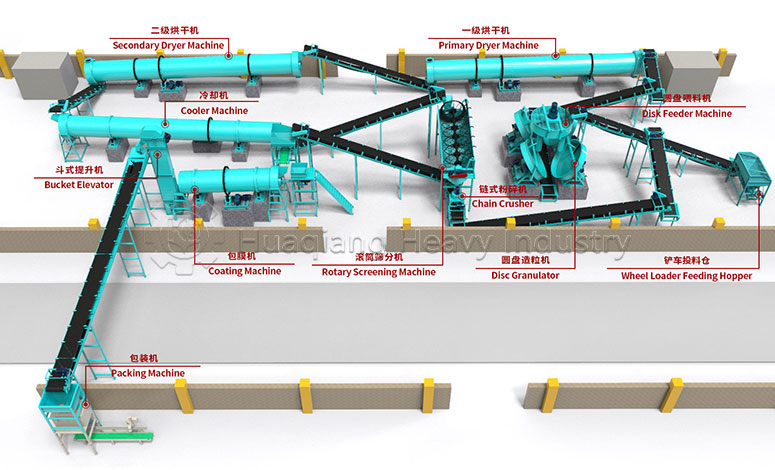

- Granulator

The “Sculptor”

Rotary drum or disc granulators transform powder into uniform 2-5mm granules. By controlling rotation speed, tilt angle, and binder liquid, they create ideal particles for application while reducing dust.

- Drying & Cooling System

The “Beautician”

Three-stage dryers with counterflow coolers remove moisture without damaging nutrients. This process gives granules perfect hardness and appearance for storage and transportation.

“In NPK production lines, these five machines work like precisely meshed gears – any malfunction affects final quality. The right equipment combination ensures both efficiency and nutritional accuracy in every bag.”

The Power of Synergy

These devices form a perfect production loop: crushing ensures processability → batching guarantees formula accuracy → mixing achieves uniformity → granulation creates ideal physical form → drying enhances stability. This systematic operation enables modern NPK plants to efficiently produce various compound fertilizers for different crop needs.

Selecting the right “Fab Five” equipment combination gives your NPK production line both a powerful heart and a sharp brain for efficient, precise fertilizer manufacturing.