For a chicken manure organic fertilizer plant with 2 million chickens, the required organic fertilizer production line generally has an output of more than 100,000 tons. Its specific configuration includes:

Fermentation system: It consists of a feed conveyor, a biological deodorizer, a mixing mixer, a hydraulic lifting and turning machine, and an electrical automatic control system.

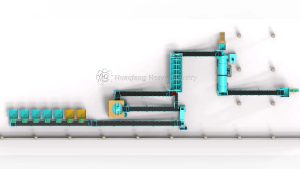

Drying system: The main equipment includes a belt conveyor, a rotary dryer, a cooler, an induced draft fan, a hot air furnace, etc.

Deodorization and dust removal system: It consists of a sedimentation chamber, a dust removal chamber, etc.

Batching system: Dynamic automatic batching system or static batching machine.

Mixer: vertical mixer, horizontal mixer, double-shaft high-power mixer, drum mixer, etc.

Conveying equipment: belt conveyor-mobile belt conveyor, fixed belt conveyor, etc.

Pelletizing equipment: disc granulator, new wet granulator, shot blasting machine, drum granulator, etc.

Drying and cooling equipment: rotary dryer and rotary cooler, etc.

Screening equipment: drum and vibrating screening machines, divided into three-stage screens, two-stage screens, etc., sealed, with beaters and non-stick walls.

Coating equipment: rotary coater, etc.

There are many factors to consider when opening a chicken manure organic fertilizer plant, including equipment investment, plant construction, raw material costs, labor costs, etc. If you still don’t know what kind of organic fertilizer production line is suitable for you, please contact Huaqiang Heavy Industry for further information. We will tailor a chicken manure organic fertilizer production line for you according to the actual situation.