Converting powdered raw materials into uniform granules is a critical step in the production process of industries like fertilizer and feed.

The disc granulator machine is the core equipment system that achieves this transformation. Through unique mechanical principles and precise process control, it completes the transformation from loose powder to uniform granules.

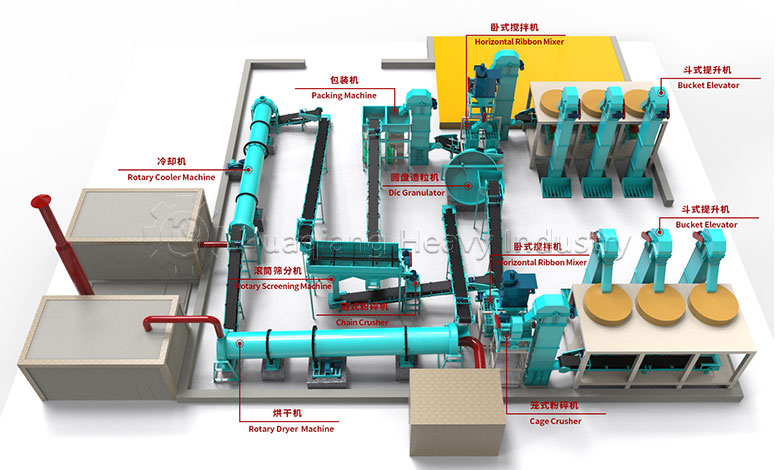

Generally speaking, a relatively complete disc granulation production line is composed of a fertilizer batching machine, a fertilizer crusher machine, a fertilizer mixer machine, a fertilizer granulator machine, a fertilizer dryer machine, a fertilizer cooler machine, a fertilizer screening machine, a fertilizer coating machine, and a fertilizer packaging machine, among which the disc granulator is the main equipment in the disc granulator production line.

Working principle

The bottom of the granulation disc is reinforced with multiple radiant steel plates ,which is study and durable ;the thickened,weighted and sturdy base design dose not require anchor bolts for fixed and working smoothly .The main gear of disc granulator uses high frequency fire ,the service life is twice than before. The inside of granulation disc is durable after corrosion treatment.

The disc granulator uses wet granulation method and compact design ,it has characteristics of uniform granulation ,high granulation rate ,products looks beautiful ,size and diameter can be controlled and so on

The process begins with liquid binding agents utilizing cohesive force to agglomerate fertilizer powder. Subsequently, the rotational speed of the disc generates centrifugal motion, causing the powder to roll and form spherical granules.

Advantages

The finished fertilizer granules formed by the disc granulator have the characteristics of beautiful appearance, uniform granulation, high granule strength, high pelletizing rate, low energy consumption and long service life and so on.