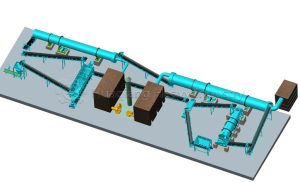

Livestock manure is rich in organic matter and nutrients, and is an indispensable nutritional resource for crop production. After simple processing, it can become an organic fertilizer that replaces some chemical fertilizers. Huaqiang Heavy Industry briefly introduces the granular organic fertilizer production process based on animal manure.

1. Fermentation and composting: Add straw, branches, mushroom residue and other auxiliary materials to livestock and poultry manure in a ratio of 7:3 to adjust the carbon-nitrogen ratio and moisture. Then sprinkle aerobic fermentation bacteria and let it ferment for about 25-45 days. During the fermentation process, the pile should be turned according to the temperature change of the pile. It is recommended to use a compost turning machine to save labor costs and improve fermentation efficiency.

2. Material crushing: After 25-45 days of fermentation and composting, livestock and poultry manure becomes gray-brown and odorless. Large lumps, bones, pebbles, etc. in the material can be crushed using a vertical high-humidity material crusher.

3. Adding nutrients: In order to make the organic fertilizer more nutritious, you can add an appropriate amount of trace elements, humic acid and other nutrients. The dynamic batching machine can accurately control the amount of ingredients.

4. Mixing evenly: After adding the ingredients, you need to fully mix the ingredients with the organic fertilizer. If the amount is relatively small or you want to save investment costs, you can mix it manually. If the amount is relatively large, it is recommended to use a mixer.

4. Mixing evenly: After adding the ingredients, you need to fully mix the ingredients with the organic fertilizer. If the amount is relatively small or you want to save investment costs, you can mix it manually. If the amount is relatively large, it is recommended to use a mixer.

5. Granulation: Common granulation equipment includes disc granulators, stirring tooth granulators and drum stirring tooth granulators. You can choose the appropriate granulation equipment according to the actual situation.

6. Drying: The formation of particles requires the addition of water, so the particles need to be dried after granulation to prevent sticking.

7. Cooling: The dried granular organic fertilizer needs to be cooled for easy storage. If the output is less than 3 tons per hour or there is enough drying space, the organic fertilizer can be cooled by itself, otherwise it needs to be cooled by a cooler.

8. Finished product screening: In order to make the organic fertilizer particles uniform in size and sell at a higher price, the size of the organic fertilizer particles should be screened. Organic fertilizers that do not meet the size should be returned to the crushing stage for re-granulation.

9. Packaging: Qualified finished granular organic fertilizers are quantitatively weighed and packaged through an automatic packaging machine.

The above is the granular organic fertilizer production process based on animal manure. If you want to know more, please contact Huaqiang Heavy Industry.