A Silent Revolution in Agriculture

Have you noticed that more and more farms and fertilizer producers worldwide are turning to disc granulation production line? This is no coincidence. From smart greenhouses in the Netherlands to rural cooperatives in India, from large-scale farms in the United States to ecological parks in China, this seemingly quiet technological transformation is redefining modern fertilizer production. Why has this equipment gained such widespread favor? The answer lies in its design philosophy and systems thinking.

Five Core Advantages: Secrets to Excellence

- The Art of Natural Granulation

Disc granulators mimic nature’s most elegant agglomeration process—like snowflakes taking shape as they roll. This granulation method, based on physical principles rather than chemical force, preserves the biological activity of organic matter. In contrast, the high temperature and pressure of traditional extrusion granulation often destroy beneficial microorganisms, reducing fertilizer efficacy. Data from the German Agricultural Research Institute shows that organic fertilizers produced by disc granulation contain 47% more active microorganisms than those produced by extrusion.

- A Model of Energy Efficiency

In an era of rising energy prices, efficiency determines success. Disc granulation production lines consume 30%-40% less energy than traditional extrusion systems, meaning approximately $15-20 in electricity savings per ton of granular fertilizer produced. The numbers from a medium-sized fertilizer plant in California, USA, are impressive: after installing a disc granulation line, annual energy costs dropped from $125,000 to $83,000, with full investment recovered within three years.

- Exceptional Granule Quality

Granule uniformity directly affects fertilization effectiveness and crop absorption. Disc granulation produces granules with excellent sphericity and consistent size distribution, offering three key advantages: reduced dust loss, improved precision in mechanical application, and enhanced storage stability. A Dutch study found that wheat fields using disc-granulated fertilizer showed a 22% increase in nitrogen use efficiency and a 35% reduction in runoff loss.

- Flexible Raw Material Adaptability

Whether it’s crop straw, livestock manure, food processing waste, or urban organic waste, disc granulators can handle it all. This versatility comes from their modular design—by changing discs with different aperture sizes, particle size can be adjusted; by modifying inclination angle and rotation speed, different moisture levels and ingredient compositions can be accommodated. A cooperative in India successfully uses this feature to seasonally process three main raw materials—rice straw, bagasse, and cow dung—enabling year-round production.

- Complete System Integration

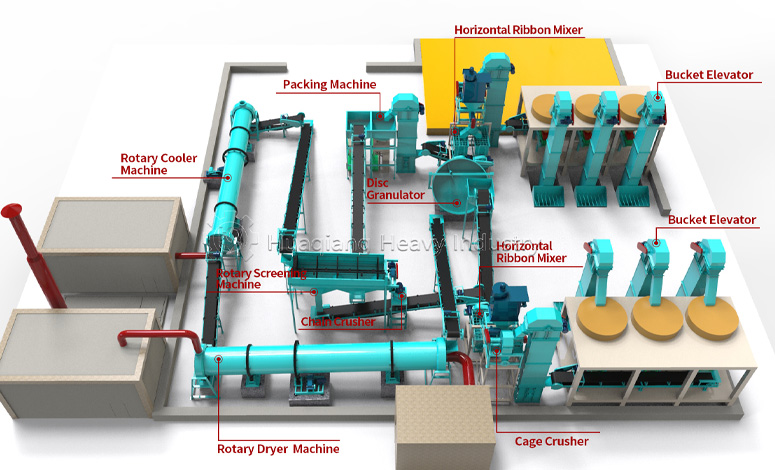

The true power of organic fertilizer disc granulator lies in how they collaborate with other equipment. Modern production lines typically include:

Pretreatment units: Crushers, screens, and batching systems ensure raw material quality and proportions

Fermentation systems: Aerobic fermentation equipment such as chain compost turner promotes organic decomposition and pathogen elimination

Post-processing equipment: Dryers, coolers, and screens optimize final granule quality

Intelligent control systems: Automated monitoring and regulation of the entire production process

Success Stories: Proof from Theory to Practice

India: Collective Wisdom of Small Farmers

In Maharashtra, India, 500 small farmers formed a cooperative to jointly invest in a disc granulation line. They collectively process their rice straw, bagasse, and cow dung, not only solving the pollution problem of field burning but also creating stable additional income. Each farmer earns about $300 more annually while obtaining high-quality organic fertilizer for their own fields, forming a virtuous cycle.

USA: Sustainable Innovation in Winemaking

Wine estates in Napa Valley, California, discovered that grape skins, seeds, and stems from the winemaking process are excellent raw materials for organic fertilizer. They customized a small disc granulation line to convert these by-products into vineyard-specific fertilizer. This innovation brought triple benefits: zero-waste production, reduced fertilizer costs, and improved grape quality. Sommeliers even noted increased complexity in wines from vineyards using the estate-made organic fertilizer.