For entrepreneurs planning to build a factory, the first and most critical question is, “What fertilizers sell well?” The answer depends on two core factors: regional demand and local competition—ignoring either can lead to product overstock and wasted investment.

Regional demand directly influences product selection. In southern China, where cash crops such as fruits, vegetables, and tea dominate, bio-organic fertilizers are in high demand. These crops require soil improvement and high-quality nutrients to enhance flavor and yield, making high-value bio-organic fertilizers a top choice for farmers. For example, in Guangdong’s vegetable-growing areas, sales of bio-organic fertilizers have grown by 15% annually in recent years as farmers prioritize chemical-free farming to meet market demand for green agricultural products.

In contrast, northern China’s major grain-producing regions (Northeast and North China) rely heavily on nitrogen, phosphorus, and potassium compound fertilizers and bulk blends. Wheat, corn, and rice require a balanced supply of nitrogen, phosphorus, and potassium to ensure stable yields. While NPK compound fertilizers with standard ratios (e.g., 15-15-15) are the mainstay in the region, bulk-blended fertilizers offer flexibility—farmers can adjust the formula to suit soil conditions (for example, adding more potassium in saline-alkali soils). A survey in the Heilongjiang Corn Belt revealed that over 70% of farmers prefer bulk-blended fertilizers due to their cost-effectiveness and adaptability.

The competitive landscape also dictates differentiation. If a region already has many small and medium-sized organic fertilizer plants, they should avoid homogenization. Instead, they should focus on high-content organic-inorganic compound fertilizers—combining organic matter with trace elements—to fill market gaps. For example, in Shandong Province, where organic fertilizer plants are densely populated, a new plant launched a 50% organic compound fertilizer for greenhouse growers, quickly capturing 10% of the local market share within six months.

For NPK compound fertilizers, customized formulas are possible if local competition is fierce. Saline-alkali regions like Hebei and Inner Mongolia require NPK compound fertilizers with salt-tolerance additives. A local fertilizer manufacturer developed a specialized nitrogen, phosphorus, and potassium (NPK) fertilizer formula (20-10-15, with added humic acid) that provides nutrients while improving soil structure, making its product stand out from the crowd.

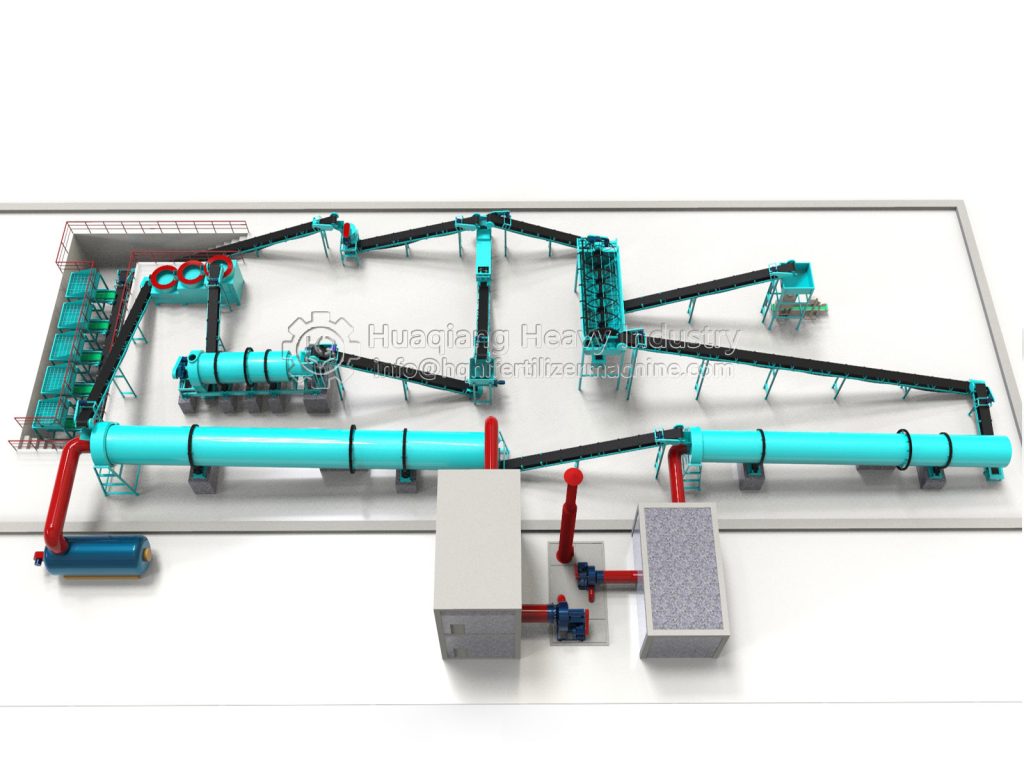

The manufacturing flexibility for such specialized formulations is achieved through adaptable production systems. A standard npk fertilizer production line can be configured to accommodate these custom recipes, beginning with precise formulation using an npk blending machine. The granulation process can utilize either a traditional disc granulator operating within a disc granulation production line or a double roller press granulator for dry granulation. This versatility allows the same npk fertilizer line to produce various specialized formulas, while the core fertilizer granulator technology remains consistent, distinguishing the process from a standard organic fertilizer production line.

In short, the choice of what to produce isn’t random. By tailoring its products to regional crop needs and differentiating them from competitors, the fertilizer manufacturer can ensure its products are a hit from the start.