In modern fertilizer production plants, the disc granulator has become the star equipment with its elegant rotating motion. This seemingly simple disc contains tremendous potential to transform agricultural production.

The charm of the disc granulator lies in its unique working principle. When materials are evenly fed through the inlet, the tilted disc begins to rotate gently, much like a skilled chef kneading dough. The powdered raw materials continuously tumble, collide, and coalesce within the disc, gradually forming uniformly sized pellets. This seemingly simple mechanical process perfectly simulates how pearls form in nature—layer by layer, growing steadily.

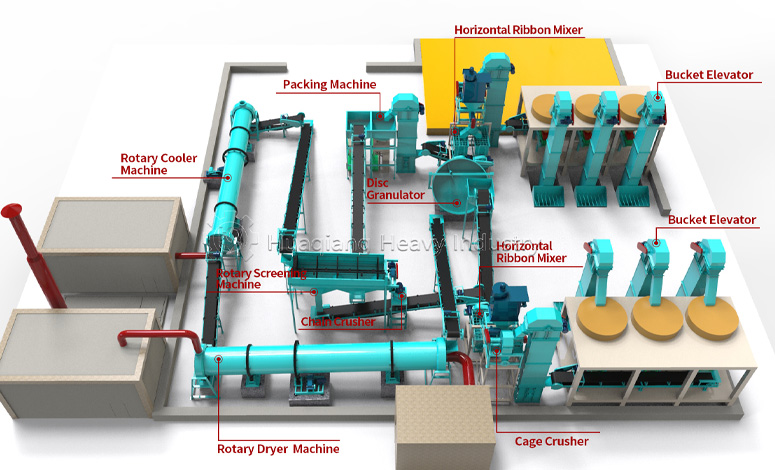

But the disc granulator doesn’t work alone. On the disc granulation production line, it collaborates seamlessly with crushers, mixers, dryers, coolers, and packaging machines, together forming a complete fertilizer production system. The chain crusher first processes raw materials into fine powder, the mixer ensures thorough blending, then the disc granulator transforms these mixtures into regular pellets, and finally, the dryer and cooler complete the product’s final processing.

The advantages of this coordinated operation are evident: the disc granulator produces uniform, appropriately firm pelletized fertilizers, while the supporting equipment ensures production efficiency and product quality. More importantly, this production line offers exceptional adaptability—simply by adjusting the disc’s inclination angle and rotation speed, it can produce various types of fertilizers including organic, compound, and bio-fertilizers.

In today’s increasingly environmentally conscious world, disc granulation production lines demonstrate unique eco-friendly advantages. They can transform agricultural waste like livestock manure and crop residues into valuable organic fertilizers, achieving resource recycling. Meanwhile, pelletized fertilizers reduce dust pollution during application and improve fertilizer utilization rates, providing strong support for sustainable agricultural development.

With the introduction of intelligent control technology, modern disc granulation production lines are becoming more precise and efficient. Automated control systems can monitor and adjust parameters in real-time, ensuring process stability and product consistency. This not only reduces labor costs but also ushers fertilizer production into a new era of intelligent manufacturing.

From traditional to modern agriculture, from extensive production to precision manufacturing, disc granulation production lines are driving global agricultural transformation in their unique way. This continuously rotating disc not only produces nutrients for crops but also carries humanity’s aspirations for green agriculture.