In the field of particle manufacturing that pursues efficiency, energy savings, and a drying-free process, a unique technological path is gaining increasing attention—the roller press granulator production line. It abandons traditional wet agglomeration or high-temperature melt processes, instantly compacting dry powders into high-density granules through pure mechanical high pressure. This production line is an outstanding representative of “dry granulation,” particularly suitable for processing heat-sensitive, moisture-sensitive materials, or those requiring high hardness. It pioneers a new, simple, and highly efficient path to granulation.

Core Advantages: Dry Process, Energy Efficient, High Strength, and Flexible

The essence of roller press granulation is physical compaction, which grants it a series of unique advantages distinct from wet processes:

Pure Dry Process, No Drying Step: This is its most notable energy-saving advantage. Material remains dry throughout (moisture content typically <5%), yielding dry granules directly after forming. This completely eliminates the highly energy-intensive drying and cooling stages required in traditional wet granulation, significantly reducing both investment and operating costs.

Exceptionally High Granule Density and Strength: Under linear pressures ranging from tens to hundreds of megapascals, powder particles are forcibly compressed, deformed, and interlocked to form very dense granules or flakes with extremely high mechanical strength. The product offers excellent resistance to crushing and abrasion, facilitating storage and long-distance transport. Its slow dissolution also enables controlled nutrient release.

Ideal for Heat & Moisture-Sensitive Materials: Since the process involves no heating or liquid phase addition, it perfectly avoids the deactivation or denaturation of active ingredients (e.g., certain microbial agents, vitamins, water-decomposing chemicals) during granulation, greatly broadening the range of materials that can be granulated

Formulation Flexibility, Easy Changeover: The production line has low requirements for raw material binders, relying primarily on physical interlocking. Changing the press rolls with different shapes (e.g., hemispherical, oblate, bar-shaped) or surface patterns allows for quick alteration of product appearance and size, flexibly adapting to small-batch, multi-variety production needs.

Environmentally Friendly, No Waste Emissions: The entire process generates no wastewater or exhaust gases. Dust is collected via enclosed systems and dust collectors and can be directly recycled, making it a clean and environmentally friendly production process.

Full Process Analysis: The Journey from Powder to Dense Granules

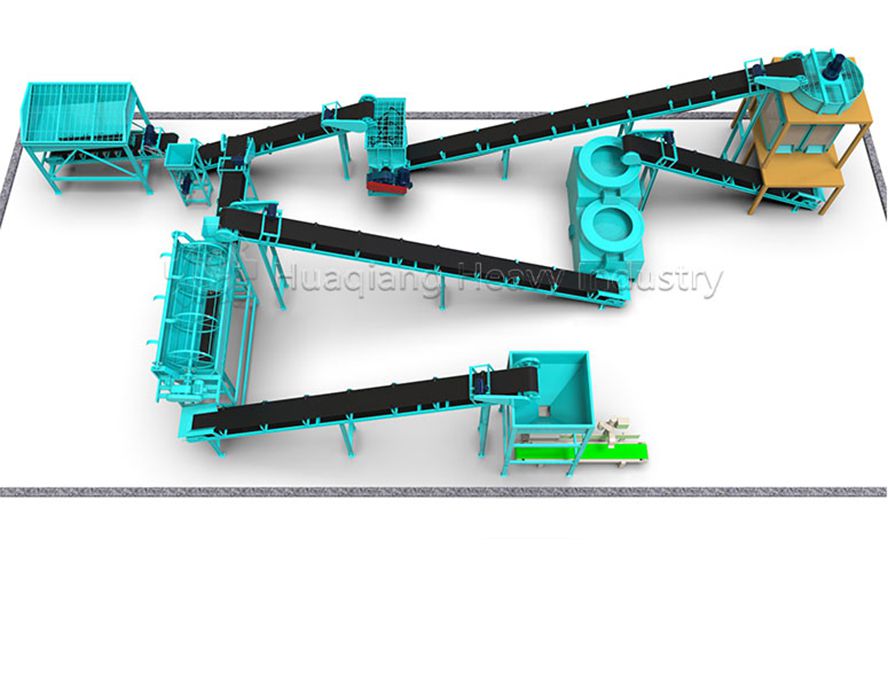

A typical roller press granulation line is an efficient, compact dry physical processing line:

Raw Material Pre-treatment & Batching Section:

Key Equipment: Crusher, Screener, Precision Feeders.

Raw materials (e.g., fertilizer salts, minerals, chemical powders) are first processed by a Crusher to achieve the required fineness (typically 80-200 mesh) and ensured for uniform particle size by a Vibrating Screen. Multiple ingredients are metered and pre-mixed according to the formula ratio by high-precision Loss-in-Weight Feeders or Volumetric Feeders.

Uniform Mixing Section:

Key Equipment: High-Efficiency Double Shaft Paddle Mixer or Horizontal Ribbon Mixer.

The batched materials enter the Mixer for thorough, uniform dry mixing. This ensures even distribution of all components at the microscopic level, a prerequisite for obtaining finished granules with consistent composition.

Core Compaction Granulation Section:

Key Equipment: Double Roller Press Granulator.

The uniformly mixed dry powder is forcibly and steadily fed by a Uniform Feeder into the nip between two parallel, counter-rotating press rolls. The roll surfaces are machined with dense, symmetrical pockets (cavities). Under enormous hydraulic or mechanical pressure (50-150 MPa), the material is instantly compacted into dense flakes (briquettes) within these pockets.

Crushing & Sizing Section:

Key Equipment: Crushing Mill (e.g., Chain Crusher, Roller Crusher).

The flakes exiting the press are sheet-like or large agglomerated pieces. A Crushing Mill is required for gentle crushing to break them down into near-final required individual granule sizes.

Screening & Polishing Section:

Key Equipment: Vibrating Screen, Drum Polisher.

The crushed material enters a vibration screener machine for classification. On-spec granules proceed to the finished product stream; over-fine powder returns to the mixer for re-granulation; oversized particles are returned to the crusher. To further enhance surface smoothness and strength, qualified granules may enter a Drum Polisher for polishing and de-dusting.

Finished Product Packaging & Dust Collection System:

Key Equipment: Automatic Packaging Scale, Centralized Dust Collector.

Finished granules are weighed and bagged by an Automatic Packaging Scale. The entire line operates under negative pressure, with dust generation points connected to a Centralized Dust Collection System (e.g., pulse-jet bag filter), ensuring a clean workshop environment.