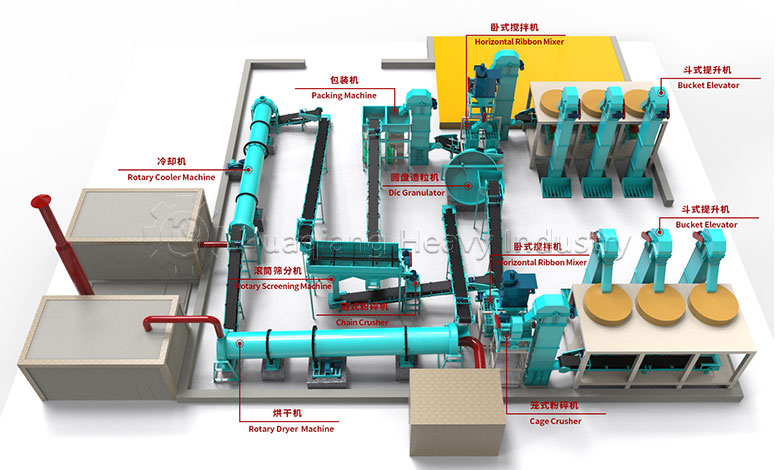

Amidst the continuous advancements in fertilizer processing equipment, disc granulator production lines, with their high efficiency and energy-saving advantages, are becoming a popular choice for NPK compound fertilizer and organic fertilizer processing. This production line, with a disc granulator at its core and equipped with a variety of supporting equipment, streamlines the fertilizer granulation process and enhances the quality of the finished product, creating new development opportunities for fertilizer companies.

The pre-treatment stage of the production line is fundamental to ensuring granulation quality. A raw material crusher first pulverizes lumpy fertilizer or decomposed organic fertilizer into a fine powder, preventing large impurities from affecting the granulation process. Next, a batching mixer precisely mixes nitrogen, phosphorus, potassium, and other raw materials or organic fertilizer with a binder according to a pre-set formula and thoroughly stirs them to create a uniform granulation material. This step acts as a “preparation” for granulation and directly determines the nutritional balance of the subsequent granules.

The disc granulator is the core component of the production line. It utilizes an inclined disc design. By adjusting the rotational speed and inclination angle, the raw materials are continuously tumbled and agglomerated within the disc, gradually forming uniformly sized pellets. Compared to other pelletizing equipment, the disc pelletizer not only boasts high pelletizing efficiency, capable of processing several tons of raw materials per hour, but also offers flexible control over pellet diameter to meet the fertilization needs of different crops. Furthermore, its simple structure and ease of maintenance reduce the company’s operating costs.

After granulation, the material enters the post-processing stage. First, a drum fertilizer dryer uses hot air to dry the wet granules to the desired moisture content, preventing clumping. Next, a cooler rapidly lowers the temperature of the granules, improving their hardness and stability. Finally, a screening machine removes unqualified small particles and fines, which are returned for re-granulation. The qualified granules are then packaged in a packaging machine, resulting in finished fertilizer ready for shipment.

Currently, disc granulator production lines are being upgraded to be more intelligent and environmentally friendly. Some lines are equipped with intelligent monitoring systems that can adjust parameters such as disc speed and drying temperature in real time to ensure stable production. The addition of dust collection devices also reduces dust pollution during the production process.