In the fertilizer industry, roller press granulation production lines have become the preferred process for forming powdered materials due to their high efficiency, energy saving, and strong adaptability. The double roller press granulator, as the core equipment, directly affects the pellet forming rate, strength, and production efficiency.This granulation method fundamentally avoids the energy-intensive drying process required in traditional wet granulation, greatly reducing energy consumption and production costs.

The roller press granulation line utilizes a non-drying, room-temperature process, offering significant advantages in energy conservation and improved production efficiency. The core operating principle of the double roller press granulator is to force a properly proportioned mixture through a feed mechanism into the gap between a pair of equal-sized, rotating extrusion rollers. Mechanical pressure compresses the powdered material, forcing it through the die holes to form uniform spherical granules.

The advantages of the double roller press granulator are that it adopts dry granulation technology, has a high ball forming rate, low dryness, and has the characteristics of low investment and quick results. The fertilizer is granulated by extrusion, and the finished fertilizer particles are dense and not easy to break, which reduces the loss caused by long-distance transportation.Double roller press granulator is widely used in organic fertilizer, compound fertilizer, feed and other industries

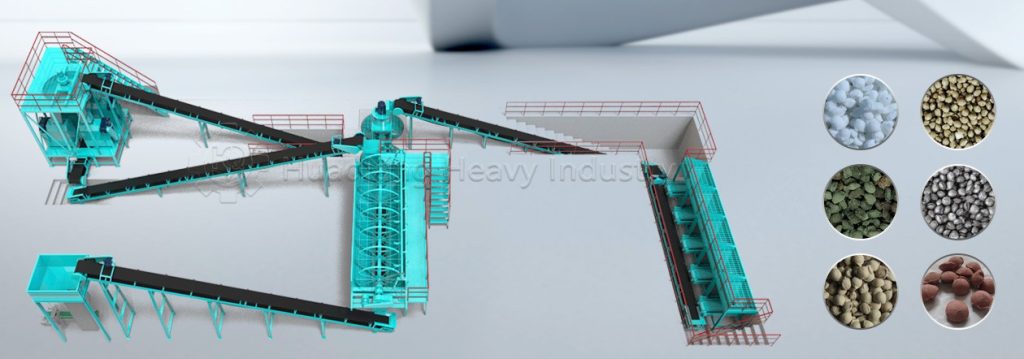

A complete roller press granulation production line usually includes: pre-treatment equipment, mainly fertilizer crusher machines and fertilizer mixer machines, to ensure the fineness and uniformity of the fertilizer, core equipment, double roller press granulator, to granulate the fertilizer, post-processing equipment, mainly fertilizer screening machines, fertilizer coating machines, and fertilizer packaging machines, to ensure the quality of fertilizer granules.