The double-shaft mixer represents a significant advancement in modern industrial mixing technology, addressing the challenges of handling high-viscosity materials through its unique design.

Core Working Principle

The core of the double-shaft mixer lies in its dual-shaft design, where two mixing shafts typically rotate in opposite directions, creating complex three-dimensional mixing movements. This design generates four key mixing effects:

- Convective Mixing:Large-scale circulating flow of materials within the mixing tank

- Shear Mixing:Refinement and dispersion of materials through velocity gradients

- Diffusive Mixing:Random movement between material particles ensuring microscopic uniformity

- Impact Mixing:Breaking up agglomerates through blade impact on materials

Equipment Structure and Composition

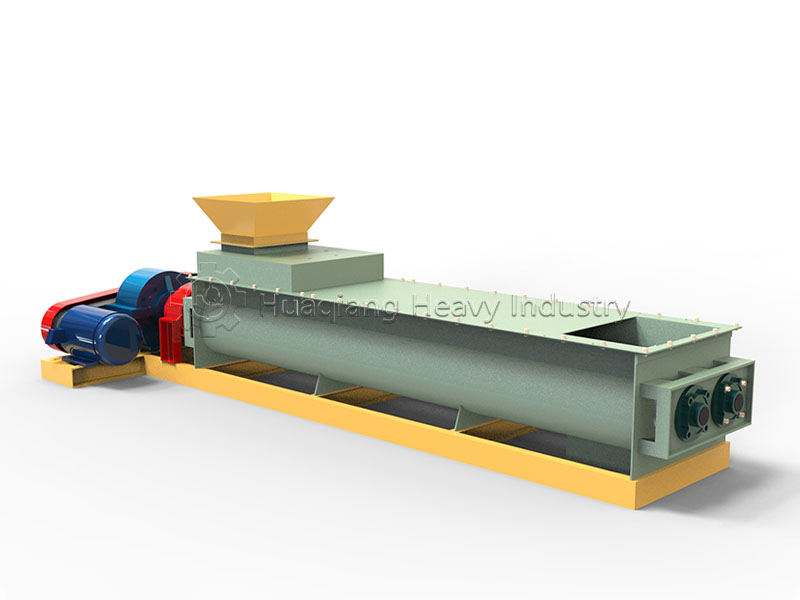

The precision design of the double-shaft mixer ensures its exceptional performance:

Mixing Tank: Manufactured from high-quality stainless steel or carbon steel, with inner surfaces typically polished to ensure no dead corners and easy cleaning. The tank design considers heat exchange requirements and can be configured with jackets for heating or cooling.

Dual-Shaft Mixing Device: Specially designed blades installed on the two mixing shafts, common configurations include:

- Paddle blades – providing powerful propulsion and turning action

- Spiral ribbon blades – achieving compound axial and radial movement

- Specialty blades – custom-designed for specific material characteristics

Drive System: Utilizing two independent motors and reducers, synchronized through precision gears to ensure coordinated operation of both shafts. Advanced frequency control allows precise speed adjustment within the 5-80 rpm range.

Sealing System: Employing multiple sealing designs, including mechanical seals, packing seals, and gas seal options, ensuring no leakage under vacuum or pressure conditions.

Feeding and Discharging System: Equipped with large feed openings and multiple discharge options, including pneumatic valves, slide valves, or screw dischargers, meeting various operational requirements.

Control System: Integrated PLC and touchscreen interface enabling recipe management, process monitoring, data recording, and remote communication functions.

Industrial Application Advantages

The unique design of the double-shaft mixer demonstrates significant advantages across multiple industries:

- Chemical Industry:Handling a wide range of materials from low-viscosity liquids to high-viscosity pastes

- Pharmaceutical Industry:Compliance with GMP standards ensuring batch-to-batch consistency

- Food Industry:Gentle mixing preserving material characteristics and nutritional components

- Building Materials:Efficient processing of dry powder mixtures containing solid particles

- New Energy Materials:Precise control of mixing uniformity for electrode materials

Technical Advantages Summary

The double-shaft mixer represents a significant technological advancement over traditional single-shaft equipment, delivering remarkable efficiency gains across various fertilizer production applications. In the npk fertilizer production line, this innovative mixer reduces processing time by 30-50% while lowering energy consumption by 20-35%, achieving mixing uniformity exceeding 95%. Its superior performance makes it particularly valuable in the npk blending machine segment, where precise nutrient distribution is critical.

This mixing technology seamlessly integrates with downstream equipment in both organic fertilizer production line and bio organic fertilizer production line configurations. The consistent output quality ensures optimal material preparation for various fertilizer granulator systems, whether feeding a disc granulator in a disc granulation production line or supplying material to a double roller press granulator. The modular design facilitates quick maintenance and cleaning, minimizing downtime throughout the entire npk fertilizer line while maintaining the precise process control necessary for high-quality fertilizer production.