In today’s era of agriculture that pursues efficiency and environmental protection, fertilizer granulation technology is quietly leading a revolution. The disc granulation production line, as a core equipment, has become a star in fertilizer manufacturing due to its unique granulation method and high production capacity. But have you ever wondered about the intricate collaboration and innovative wisdom behind this production line? It is not just a simple mechanical system but a complete solution that integrates multiple devices, aiming to transform raw materials into uniform, easy-to-use granular fertilizers, supporting global agricultural sustainability.

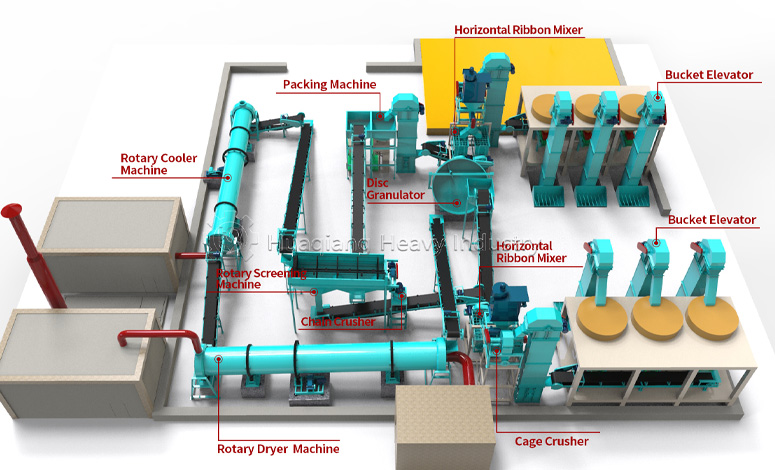

The heart of the disc granulator lies in its tilted rotating disc design, which uses a clever balance of centrifugal force and gravity to make wet materials roll and agglomerate in the disc, forming uniformly sized particles. This process is like the “snowball effect” in nature, being both energy-saving and efficient. Coupled with auxiliary equipment such as vertical disc mixer, dryers, coolers, and screening machines, the entire production line achieves seamless integration from mixing and granulation to drying and grading. For instance, mixers ensure even blending of raw materials, while dryers quickly remove moisture to enhance fertilizer stability. This integrated design not only boosts production efficiency but also significantly reduces energy consumption, making fertilizer products better suited for modern precision agriculture.

Moreover, the flexibility of the disc granulation production line is astounding. It can adapt to various fertilizer types, such as organic fertilizers, compound fertilizers, and even specialty fertilizers, meeting the nutritional needs of different crops. As global calls for green agriculture grow louder, this low-emission, high-recovery equipment is becoming an ideal choice for farms and fertilizer plants. It not only improves fertilizer utilization and reduces environmental pollution but also cuts labor costs through automated controls. In the future, with the integration of smart technologies, disc granulation production lines will become more intelligent and personalized, injecting new vitality into world food security.