In modern agriculture, NPK compound fertilizers have become the “golden formula” for crop nutrition. But have you ever wondered how those uniform, plump fertilizer granules are produced? An efficient NPK fertilizer production line is like a well-trained symphony orchestra, where every section needs to perform in perfect harmony.

Core Equipment: The “Backbone” of Production

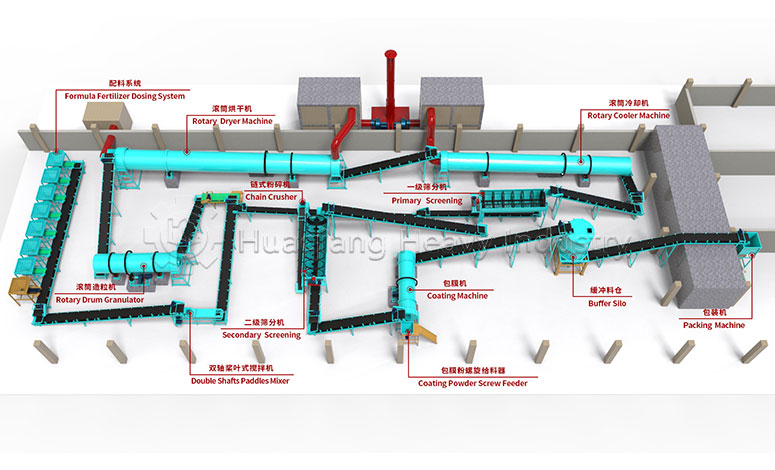

Imagine the magical transformation from raw materials to refined granules—what key fertilizer equipment makes this possible? First comes the raw material processing system, acting as the outpost of the production line, responsible for fertilizer crusher and fertilizer screener machine various materials to ideal particle sizes. Then comes the mixing and granulation system—the “heart” of the entire line—where nitrogen, phosphorus, and potassium elements waltz in rotating granulators, gradually forming perfect spherical granules.

The drying and cooling system plays the role of “beautician,” removing excess moisture and setting the granules. Finally, the screening and packaging system acts as the quality inspector, ensuring only qualified products are “dressed” and sent to market.

Smart Control: The “Brain Center” of Production

The most amazing aspect of modern NPK production lines is their level of intelligence. Through PLC control systems, the entire production line seems to come alive:

Real-time monitoring of each section’s operation status

Automatic adjustment of process parameters

Precise control of product quality

Remote diagnosis of equipment faults

Particularly impressive are the advanced adaptive control systems that automatically adjust process parameters based on subtle raw material variations