In modern agricultural production, fertilizer manufacturing has evolved into a precise combination of science and art. The disc granulation production line, as a core innovation in this field, is redefining the standards of efficient fertilizer production. But have you ever wondered how this seemingly simple disc transforms powdered raw materials into uniform granular fertilizer? More intriguingly, how does it collaborate with other key equipment to form a complete production system?

Core Principles of Disc Granulation

Disc granulator are renowned for their uniquely inclined disc design, typically adjustable at angles between 35-55 degrees. When raw material powder is fed from the top, the rotating disc generates centrifugal force, causing the material to rise along the disc wall and then roll downward under gravity, creating a “snowball” agglomeration effect. This process, known as “rolling granulation,” is a perfect industrial application of natural agglomeration phenomena.

Compared to traditional extrusion granulation, disc granulation offers four distinct advantages:

High Granule Uniformity

Naturally rolled granules have good sphericity and concentrated size distribution, facilitating precise fertilization.

Operational Flexibility

Different granule specifications can be produced by adjusting inclination angle and rotation speed, adapting to diverse needs.

Relatively Low Energy Consumption

Primarily relies on mechanical rolling rather than high-pressure extrusion, offering significant energy savings and reduced production costs.

Lower Maintenance Costs

Simple structure, fewer wear parts, longer service life, and reduced downtime for maintenance.

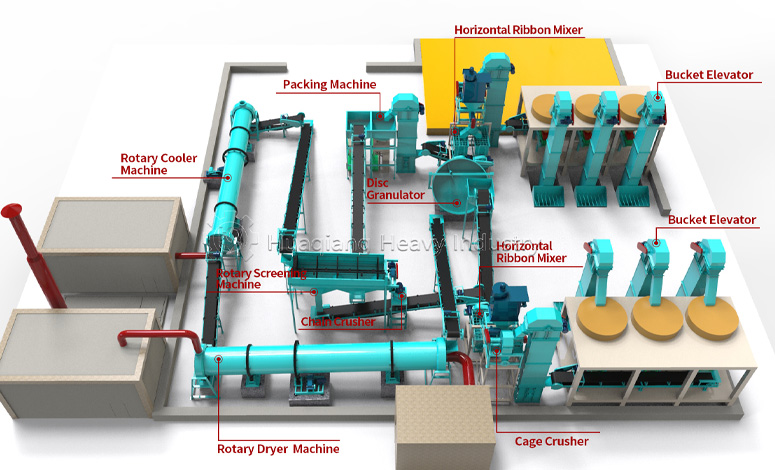

Complete Fertilizer Production Ecosystem

An efficient disc granulation production line is far more than just a rotating disc. It is a precision system where multiple pieces of equipment work in synergy, each playing an irreplaceable role:

Raw Material Preprocessing

Crushing and screening raw materials to ensure ideal particle size and purity

Core Granulation Stage

Disc granulator transforms powder into uniform granules

Post-processing & Refinement

Drying, cooling and screening to ensure final product quality

Packaging & Storage

Automated packaging and warehousing to improve overall efficiency

Raw Material Preprocessing Stage

The starting point of the production line includes raw material crushers and rotary screener machine. These ensure the raw materials achieve ideal particle size and purity, laying the foundation for subsequent granulation. Advanced automatic batching systems precisely control the proportions of various raw materials, ensuring nutrient balance in the final product.

Core Granulation Stage

Within the disc granulator, a liquid binder spraying system precisely controls the amount and distribution of binder, while a rotation speed control system adjusts granulation speed based on material characteristics. These subsystems work together to optimize granule quality and production efficiency.