In the field of particle manufacturing that pursues efficiency, energy savings, and a drying-free process, a unique technological path is gaining increasing attention—the roller press granulator production line. It abandons traditional wet agglomeration or high-temperature melt processes, instantly compacting dry powders into high-density granules through pure mechanical high pressure. This production line is an outstanding representative of “dry granulation,” particularly suitable for processing heat-sensitive, moisture-sensitive materials, or those requiring high hardness. It pioneers a new, simple, and highly efficient path to granulation.

Comparison with Other Granulation Processes

Roller press granulation occupies a unique “dry, high-pressure” quadrant in the technology spectrum:

VS Disc/Rotary Drum Granulation (Wet): Wet granulation requires adding a liquid phase (water, steam, binder) and forms spheres through tumbling agglomeration or chemical reaction, necessitating subsequent drying. It’s suitable for large-scale production. Roller pressing is pure dry, drying-free, high-density, better suited for heat-sensitive materials and products demanding high strength.

VS Flat Die Pellet Machine: These also use extrusion, but the die has through-holes; material is extruded through the holes and cut to form. Roller pressing uses enclosed pockets for compaction, operates at higher pressure, produces more regular granule shapes, e.g., hemisphere), and typically offers longer die life.

Core Role in the Production Line

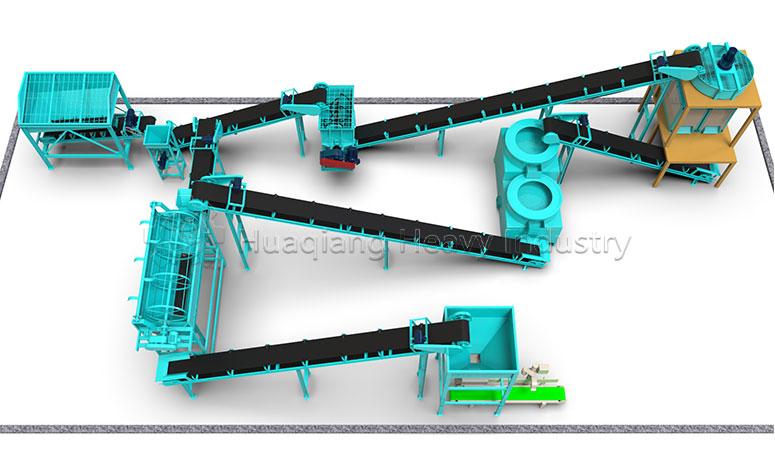

The double roller press granulator is the “heart” and core technology of the entire production line. Preceding stages like crushing, mixing, and feeding are all dedicated to providing it with qualified, uniform, stable dry powder feedstock. Its compaction effectiveness directly determines the efficiency of subsequent crushing and screening stages, as well as key quality indicators of the final product like strength and granule shape.

Application Scenarios & Value

The roller press granulator production line is the ideal choice for granulating specialty fertilizers (e.g., slow/controlled-release), chemical intermediates, mineral feeds, ceramic powders, catalyst supports, powder metallurgy products, salt products, and various fine chemicals unstable to water or heat. Its value lies in: achieving high-density granule production with minimal energy consumption, protecting material activity, delivering products with outstanding physical properties, and enabling a clean, environmentally friendly production process. It is a key technological asset for valorizing powder materials into commercial forms and meeting specific application performance requirements.

Conclusion

Choosing a roller press granulation line means selecting an efficient, energy-saving, and highly targeted dry-forming technological route. It transforms enormous pressure into precise forming force, greatly enhancing the physical form and application value of materials without altering their chemical essence. In the fields of fine chemicals, high-end agricultural inputs, and specialty material manufacturing, this “water-and-fire-free” dry process line is becoming a solid force driving product upgrades and process innovation with its unique technical appeal and economic benefits.